An international sensors leader collaborates with a custom cold forming manufacturer in order to supply a unique micro-miniature part for use in an environmental application in the automotive market.

Challenge

一家全球传感器制造和工程公司在美国设有总部,面临着关键电子连接器组件的NPD挑战。它需要设计,制造和五个Sigma流程功能来创建一个micro-electrical mechanical system (MEMS)用于汽车清洁能源排放申请。

此外,为了提供其在亚洲的全球大会运营,该公司需要100%的质量检查和JIT库存管理。

Solution

他们与位于PA Easton PA的定制冷锻造专家Sussex Wire,Inc。合作,因为传感器公司没有内部的微型手机和冷头服务来制造其组装所需的零件。

为了满足公差规格,苏塞克斯电线开发了组件几何设计,实施了100%过程中的自动化光学检查(AOI),镀上,清洁和集成了最终组装,包装和物流,以产生完整的解决方案。

Image Credit: Sussex Wire

如图1所示,微型线粘结引脚组件这是这项合作的结果,是由铜CDA 102设计和创建的,其控制尺寸公差降至+/- .00078”,次要OD为.03937”,总长度为.2118”。

作为制造商,关键考虑因素集中在维持CDA 102底物的天然机械性能,同时获得五微米以下RA的终端条件终饰。

Sussex Wire’s cold heading design engineering and manufacturing technology met the surface finish, dimensional, mechanical strength and piece part price needs uniquely, to support a successful customer MEMS automotive emission sensor market launch.

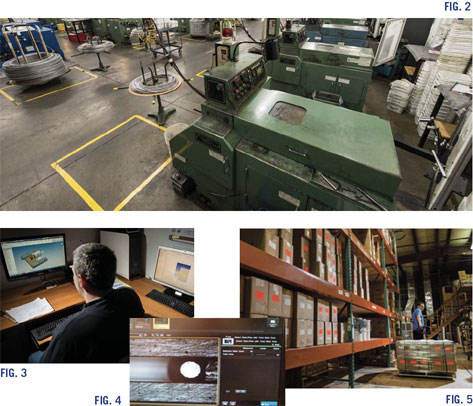

Through Sussex Wire’s proprietary part and tooling progression, vertically integrated manufacturing operations (Figure #2), incorporation of finite element analysis (Figure #3), and a proprietary Automated Optical Inspection (AOI) system developed and implemented by Sussex Wire (Figure #4), achieving and controlling a surface finish condition of a Ra of under five microns on the wirebond end was possible.

Image Credit: Sussex Wire

结果

如图5所示,通过MRP支持的拉看板库存系统执行,客户将JIT交付给其亚太合同组装运营。

Key Features

好处汽车公司希望从苏塞克斯电线等制造商那里采购定制金属零件,可以包括:

- 定制,过程中自动化光学检查系统

- Lean JIT Kanban pull inventory management

- Competencies on collaborative engineering feasibility, project management and validation

- 即使在高生产速度下,也可以保留原材料的机械性能的冷标题制造技术

- Vertically integrated tool and part design, and high volume production

此信息已从Sussex Wire Inc.提供的材料中采购,审查和改编。欧洲杯足球竞彩

For more information on this source, please visit苏塞克斯电线公司