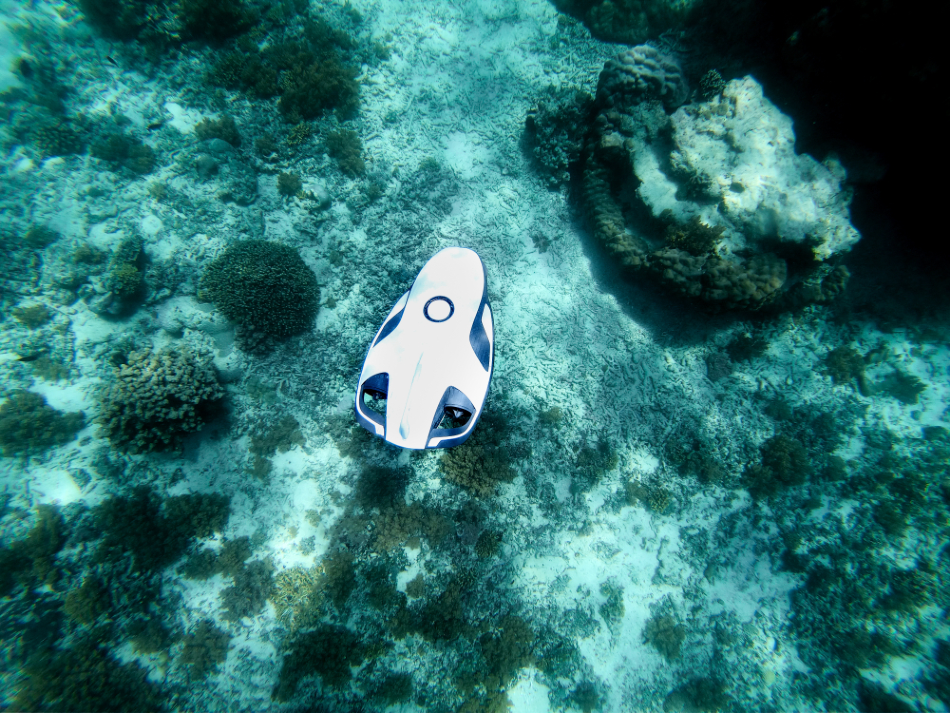

Image Credit: Kryvenok Anastasiia/Shutterstock.com

Autonomous unmanned underwater vehicles (UUVs) are used by the United States military as well as scientists gathering important data in the world’s oceans. However, these are often left in the sea when their mission is complete or retrieved from the ocean floor at significant expense. An innovative 3D-printable material can be used to make these vehicles biodegrade in marine environments at a predefined timescale.

控制退化速率

Biopolymers do already exist and are used to create machines and devices that biodegrade in marine environments. However, there has been no way of controlling the rate at which these materials degrade until now.

The new 3D printable material solves this problem. Set lifespans of the final material can be finely tuned by adding a biological material (typically agar) in set ratios to a biodegradable polymer.

This means that devices such as UUVs can be designed to biodegrade in marine environments once their mission is complete. Not only does this eliminate the expense of retrieving equipment from the ocean floor – which is necessary if, for example, the machine incorporates classified technology – but it also helps to protect the delicate ecosystems in our planet’s oceans.

What is the New Material?

The new 3D-printable material builds on existing research into marine-biodegradable polymers. The inventors identify three ideal candidates for the biopolymer base: polycaprolactone (PCL), polyhydroxyalkanoate (PHA), or polybutylene succinate (PBS). The patent also notes that other materials could be used.

这些聚合物由于各种原因而降解。例如,由于酯键的水解,PCL在水中降解,而其他材料吸引了微观海洋生物,这些海洋生物会消失在生物聚合物中的有机物中。欧洲杯足球竞彩

How is the Rate of Degradation Controlled?

新材料的发明者将三个生物聚合物确定为理想的候选者,本身不能产生根据设定的时间表生物降解的材料。欧洲杯足球竞彩

However, mixing an organic material – agar – in with the biopolymer at different ratios gives manufacturers control over the final material’s rate of degradation.

The table below indicates varying lifespans of the final material, based on the ratio of agar to biopolymer used:

所需的寿命 |

琼脂的比率 |

Ratio of biopolymer (PCL) |

Ratio of other biological materials |

0-3个月 |

50-95% |

5-50% |

1% |

3-6 months |

25-50% |

40-75% |

0.1% |

超过6个月 |

5-25% |

75-95% |

Optional |

How Do the Materials Included Affect the Final Product?

Agar is used in the new composite material as a gelling agent. In the ocean, the agar provides a structure from which enzymes and microorganisms can eat away at the biopolymer base. Because it is not digestible, controlling the ratio of agar to biopolymer material enables designers to control the final material’s rate of degradation.

In addition to agar and the base biopolymer, the inventors also experimented with the addition of other biological materials into the final composite. These can be a variety of materials selected for a variety of purposes.

For example, increasing the rate of degradation, providing a base structure upon which to grow organic structures, and even disabling explosive devices can be possible with the addition of various biological materials.

One candidate for inclusion in this way is synthetic hagfish slime, which was invented at the same US Navy laboratory.

How and Why is the New Material 3D-Printable?

The patent for the new material includes a suggested workflow for 3D printing. This makes it a more practical option for UUVs and other research machines, which are typically intended for single missions and produced with bespoke designs that fit the mission.

新材料的3D打印过程始于以所需的比率混合材料,然后将复合材料挤出到细丝中。欧洲杯足球竞彩然后可以使用传统的增材制造方法执行3D打印。

如果该复合材料需要添加其他生物材料(例如合成hag鱼泥),则必须在相对较低的温度下打印3D,以免杀死已添加的有机物。欧洲杯足球竞彩

This is possible due to the low melting point of agar (approximately 85 °C), as well as the careful selection of biopolymer base material. Biopolymer materials such as polylactic acid (PLA) and polyhydroxybutyrate (PHN) only melt when heated to 173 °C and 175 °C respectively.

但是,PCL和PHA可以在较低的温度下融化。PCL在60°C下的PCL熔体可以在40°C和180°C之间修改为熔化,具体取决于使用的起始单体。为了证明他们的方法的多功能性,研究人员还尝试了PBS,该PBS在115°C下融化,不适合与其他生物材料一起使用。欧洲杯足球竞彩

Find out more: 3D Printers and 3D Printing Equipment, Materials and Accessories

Military Applications and Beyond

As well as military and research applications, the new material could be used in a wide variety of commercial purposes. TechLink, a private organization that works with the US military to help companies commercialize military research, is offering licensing services to businesses at no cost.

The inventors of the new material – Josh Kogot, Ryan Kincer, and April Hirsch – are continuing their work at the Biotechnology Research and Development Lab in the Naval Surface Warfare Center (NSWC) in Panama City, Florida. The lab’s output will remain highly anticipated by the military, researchers and industry in years to come.

References and Further Reading

Kogot, Joshua M., Matthew R. Kincer, and April Hirsch. (2020) Review ofMarine Biodegradable Composition for 3-D Printing。US Patent Office, issued August 25, 2020.https://pdfpiw.uspto.gov/.piw?PageNum=0&docid=010752772&IDKey=&HomeUrl=http%3A%2F%2Fpdfpiw.uspto.gov%2F。

TechLink(2020)Disposable oceanic sensors, underwater vehicles? Biodegrading 3D printing material invented in Navy lab.Techlink. Available at:https://techlinkcenter.org/news/disposable-oceanic-sensors-underwater-vehicles-biodegrading-3d-printing-Material-Material-Navy-inavy-lab

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of theTerms and conditionsof use of this website.