图片来源:稳定的Micro Systems Ltd

A标准测试方法is a conclusive procedure that yields a test result. So as to achieve accurate and relevant test results, a standard test method is definite, unambiguous, and experimentally viable, as well as being reproducibly effective.

A标准测试方法can be regarded as an experiment that establishes one or more characteristics of a given sample and the detail of the test method is typically a result of creation from several experts in that measurement field.

例如,在材料测试行业中,已经开发了大量的标准方法欧洲杯足球竞彩(例如,ASTM,ISO),这些标准方法是专门用于测量样品特征的。

Standard examples of those that use Texture Analyzers or Materials Testing equipment are:

- ASTM D882-02: Tensile test of thin plastic sheeting (thickness<1mm)

- EN 1944:1996-自粘胶带 - 低速下的脱落粘附测量

With detailed results in an industrial report or academic paper, these standard-methods will have been followed closely for the collection of the results. The reason that standard methods have their place in the laboratory is that they are understood globally by others using the same standard test methods.

A great number of companies utilize one of a suite of Texture Analyzers to determine fundamental parameters that account for the dimensions and geometry of the sample as well as test set-up specifics along with the relevant engineering equations.

这种类型的测试可以简单地比较不同的样本,并与文献数据进行对比。然而,它确实需要越来越复杂的分析将力转化为压力和距离为应变。

欧洲杯足球竞彩材料参数可以在不同负载能力的一系列仪器上执行。图片来源:稳定的Micro Systems Ltd

纹理分析仪通过使用经验测量,通常用于对非常规产品的质量控制。压碎平板电脑或测量饼干在破裂之前弯曲的距离所需的力是制造商在开发新产品时寻找的关键信息,或者确保产品在点检查期间适当地执行。

这种类型的测试非常适合具有非典型几何形状的产品,但对于测试更复杂的系统(例如产品及其包装的组合)也很有用:例如一盒鸡蛋,锅里的酸奶或打开环罐的力量。

通过直接启用产品的测试,节省了时间的优势。在这里,经验测试具有位置的经典示例是显而易见的,因为这种性质的测量不属于基本材料的特定尺寸标准。欧洲杯足球竞彩

For example, in the food industry, there are fewer standard methods for physical property measurement. Yet, one of few specific standard-methods may already be in place for the testing of samples, e.g. ISO Gelatine Bloom Strength, AACC Pasta Firmness, AACC Bread Freshness, ASTM Adhesive Peel Strength, ASTM Petroleum Wax Firmness.

应用某些标准时发生的限制是,其特定的主要好处可能是对测量的劣势。运营商通常使用标准方法来测量产品的属性:

- The property that the standard-method measures is not the most crucial, or interesting, a measurement that could be performed on the sample

- 样品制备程序可能是复杂的,甚至不可能与要测试的样品不同于开发测试方法的样品的不同。

彻底且有据可查的测试方法至关重要。更关键的是选择一种测量正确特征或属性的合适方法。并非所有的测试和测量都始终均匀有用:通常使用测试结果来预测或推断针对特定目的的适用性。

但是,测量产品的关键特征,而不是遵循未最佳表征产品的任意标准方法,这似乎更可行。

如果没有预先存在的约束和最简单的测试解决方案,则有时最好的方法是创建一个模仿现实生活中产品方式的测试。这被称为“模仿测试”,并且倾向于使对数据的解释和理解变得更加容易。

对于某些行业,几乎不可能就测量产品物理特征的方法达成协议。尽管可以在国际上达成协议,但并非总是被普遍接受。如果各组进行的研究要相互作用,方法的标准化至关重要。

用于物理测试的方法应该测量被认为是监测过程所需和必要的特征,但是它们并不总是与其他实验室相提并论,而不同的标准可能是关键。

Where the emphasis is placed on the international comparison is crucial to standardize the methodologies. This includes all aspects of the testing procedure and this is an area of primary directed for the reference methods.

通过比较,如果采用了产品的直接测量,则不应通过参考方法限制实验方法。

Rather, researchers should be motivated to design and use methodologies that improve the precision and accuracy of testing methods and develop an understanding of the basic mechanisms.

It is likely that new methods will emerge from a greater understanding of measurements that accurately predict consumer assessment of product characteristics.

稳定的微型系统范围纹理分析仪提供了测试原理的灵活性(例如,压缩,穿透,张力,挤出等)以及在软件中的探针,固定装置和数据分析技术的无限选项,用于纹理分析和测试设置,可将可以完全定制。

Whilst standard-methods are indeed useful for conventional material forms that have not been modified over the years or those that are fully accepted, there lies another world where ingenuity has expanded into new materials and material forms for which these standard-methods cannot be applied.

For example, in the field of pharmaceutical development where traditional methods are well-established for the testing of tablets, suppositories, gels, and medicated liquids that are manufactured in their traditional form.

然而,已经设计了最先进的剂型,包括瓦解膜,胶囊,可咀嚼的粘贴,可用于测量其物理(或纹理)特征。

为了促进可以测量的不同类型,尺寸和其他材料特征的范围的样品测试,需要进行非标准测试方法。

非标准方法不仅有效,如果不能与标准进行样本维度进行,以及操作员可能希望修改测试参数(例如测试速度)以密切复制样品所在的情况,则操作员可能会修改测试参数的情况。经常使用。

请注意,认识到应详细介绍测试参数或样品制备技术的交换是为了进行任何后续比较,这始终至关重要。

Data Analysis and Engineering Calculations

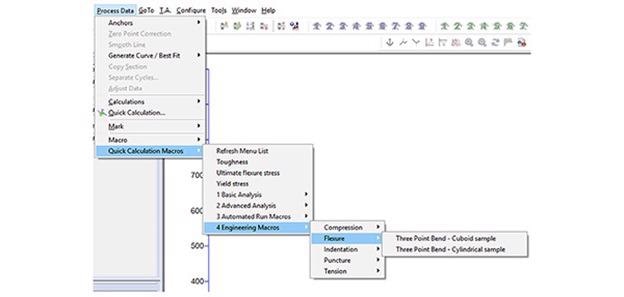

如果基本测试对操作至关重要,并且对这种测试方式没有改变的偏好,则将标准工程计算集成到指数software for rapid calculation of particular energies, moduli, stresses, strains and strengths which are specifically suited tomaterials testing申请。

每个计算都被开发用于使用非常特定的测试设置(例如,Cuboid三分弯曲测试)作为分析所需的指定方程式依赖于样品和测试几何形状。

图片来源:稳定的Micro Systems Ltd

测试类型及其分析可能性

Regardless of whether the test is performed in compression or tension, analysis of a resulting curve can be performed to obtain the following typical parameters:

- Breaking strain

- Energy to failure

- 能量到最大应力

- 滞后%

- Maximum stress

- 弹力

- 应变率

- 最大应力应变

- 屈服应变

- 切线,和弦和割线模量

- 杨的模量

- Yield stress

- x% proof stress

When specifically measuring in tension additional parameters may include:

- Necking onset

- 应变硬化参数

- 强度系数

- Ultimate tensile strength

使用三点弯曲的立方体和圆柱样品弯曲:

- 抗弯强度

- Toughness

- Yield stress

- 杨的模量

使用锥形和球形探针的凹痕:

- 弹性能量

- 硬度

- 压痕能量

- Indentation modulus

- Plastic energy

用球形探针穿刺均匀厚度薄膜:

- Failure Strain

- 刚性

- 力量

- Toughness

尽管设备可以提供直接,2020欧洲杯下注官网灵活的经验或模仿解决方案,但它也促进了材料行业内的良好常规测量。欧洲杯足球竞彩

多年来,稳定的微型系统引入了大量的测试程序和分析方法,适用于获取可以在广泛行业中使用的基本材料参数。欧洲杯足球竞彩

有关可以在材料上进行的典型纹理分析测试的摘要,请观看此视频以查看亮点:欧洲杯足球竞彩https://www.youtube.com/watch?v=D1cNQP--CZw

This information has been sourced, reviewed and adapted from materials provided by Stable Micro Systems Ltd.

有关此消息来源的更多信息,请访问稳定的微型系统有限公司。