意大利面条’s mechanical properties are key to its use and popularity. Pasta is very brittle and stiff in its dried form, but its properties significantly change when it is introduced into a humid environment and heated.

。图片来源:Perkinelmer食品安全和质量

本文着眼于在不同的等温和温度扫描条件下湿度对面食的影响。

动态机械分析(DMA)是一种用于测量材料刚度的技术。面食的刚度很好地表明了干产品的稳定性。虽然数据包的干面食相对僵硬,但湿度和温度的引入将导致其刚度随着材料变软而降低。

The modulus offers insight into the stiffness as it decreases, while tan δ highlights at what point the material becomes less elastic and more viscous.

DMA技术涉及将振荡力施加到材料上,并测量样品的结果位移。刚度可以从该测量中确定,从而可以计算模量和tanδ。

Tan δ can be understood as the ratio of the loss modulus to the storage modulus.

测量位移中的相位滞后并将其与施加力进行比较,促进了材料阻尼特性的确定。tanδ将在温度下绘制,通常将玻璃转变视为峰值。这是因为材料在穿过玻璃过渡时吸收能量。

Dried pasta may be stored for prolonged periods with no risk of biological decay. When exposed to water – via humidity or by immersion - the pasta will absorb the water and begin to hydrate. This hydration rate is impacted by humidity and temperature.

Experimental

Isothermal Experiment at 50 °C and 100% RH

For this experiment, a sample was mounted in aPerkinElmer®DMA 8000的单个悬臂弯曲夹。温度设置为50°C,当湿度达到100%时,实验开始了。

Temperature Scanning Experiment at 62% and 100% RH

For this experiment, a sample was mounted in the DMA 8000’s Single Cantilever Bending clamps, and the RH was permitted to equilibrate. Samples were run from ambient temperature to more than 100 °C.

资料来源:Perkinelmer食品安全和质量

| 2020欧洲杯下注官网 |

实验条件 |

| DMA 8000 |

样本: |

意大利面条 |

| 流体浴 |

Geometry: |

单个悬臂弯曲 |

| Humidity Generator |

方面: |

2。75 (l) x 4.50 (w) x 0.83 (t) mm |

| 循环者 |

频率: |

1Hz |

Results and Conclusion

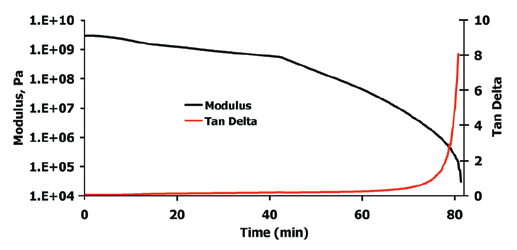

Figure 1 displays the modulus and tan δ response from a pasta sample at 50 °C and 100% RH. The modulus begins to decrease almost instantaneously upon exposure to the RH, losing all integrity at approximately 1.5 hours.

Figure 1.来自50°C的面食样品的模量和tanδ。图片来源:Perkinelmer食品安全和质量

The tan δ can be seen to increase steadily over the course of the experiment, suggesting that the sample becomes increasingly viscous and less elastic until 1.5 hours when the sample fully collapses.

在40分钟处的肩膀表示“ Al Dente”点,面食完全水合但保持相对牢固的质地。

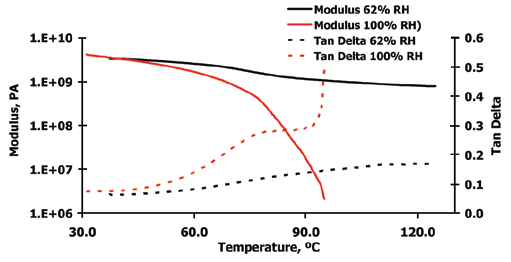

图2。Modulus and tan δ from two temperature scanning experiments. Image Credit: PerkinElmer Food Safety and Quality

图2显示了两个温度扫描实验的响应,黑线对应于62%RH的实验,红线和红线对应于100%RH处的实验。

每个实验中的模量始于相同的水平,确认检查了类似的材料。

正如预期的那样,较高的RH实验表明,模量更快地减少,最终在100°C左右失去结构完整性。62%的RH实验表明,在温度范围内,模量下降较小。

100%RH模量响应在75°C下显示出相似的肩膀。这表示pastareaching “al dente” point in line with the first graph.

The tan δ response in the 62% RH experiment demonstrates a continuing increase, highlighting increasing viscosity. This is not a constant increase (like the modulus response), suggesting that multiple processes are involved.

对于100%RH样品而言,此过程更加明显,并且更快。在75°C左右观察到一个峰 - 可能是增塑的弛豫事件,对应于“ Al Dente”点。当样品在100°C左右开始“烹饪”时,样品变得非常粘。

These experiments clearly show the DMA 8000’s capacity to perform measurements under a controlled humidity environment. The pasta in this study demonstrated notable mechanical effects as the samples’ temperature, and humidity were controlled and altered.

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer Food Safety and Quality.

有关此消息来源的更多信息,请访问Perkinelmer食品安全和质量。