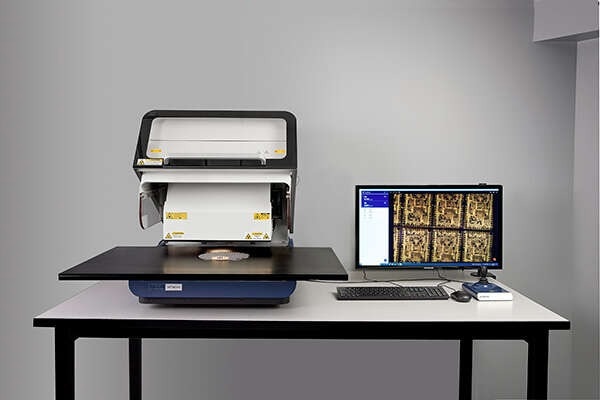

FT230涂料分析仪是用户超越舒适区并开始使用新的XRF涂料分析仪的最佳原因之一。

Image Credit: Hitachi High-Tech Analytical Science

时间就是金钱;更快地获得结果

这time it takes to locate a part, set it up in the XRF and act on the results has a significant impact on production efficiency and the cost of materials. The more time it takes, the more material plated – if that material is out of spec, it has to be scrapped for a total loss. However, if the material is in spec, users can still end up applying more coatings and use more chemicals than absolutely necessary.

这FT230已经开发出来缩短了这段时间,以便可以做出更快的决策。这是如何和结果的结果:

- Wide-view camera:使用XRF测量时要采取的第一步是找到测量位置。虽然大多数XRF分析仪中标准配置的相机非常适合微调,但很难浏览更大的零件来查找特定功能。

宽视图摄像头允许操作员查看整个可测量区域,并确保选择正确的功能(由功能强大的Zoom辅助),该功能将功能带给了十字准线。这可以节省您的设置时间的20%。

- Automated focusing: Once the location has been set, the operator must focus the part. With conventional instruments, this is completed using the focus laser or video focus.

FT230具有使用焦点激光器的能力,但还提供了两个自动焦点功能来加速和简化此步骤。自动方法可测量从X射线管到零件的距离,并自动将管驱动到预定的工作距离。

自动方法可以比焦点激光器快33%。

Auto focus, sometimes referred to as the distance independent measurement, also measures the distance between the X-Ray tube and the part, but rather than moving the tube, it ensures the tube remains at the same height and uses that distance to correct the new geometry.

Auto focus allows users to load parts of varying heights or measure parts that are recessed or stepped, and can be 62% faster than using a focus laser.

- 找到我的角色TM: For ultimate simplicity, the user only has to teach the instrument how to handle a part once. From that point on, the operator simply places a part into the instrument, runs Find My PartTM,并且,通过机器视觉,FT230能够识别零件并加载完整的分析程序 - 校准,准时大小,测量位置,工作距离,测量时间以及如何处理结果。

找到我的角色TM可以比传统设置快72%或更快。也可以通过简单地使用名称查找并扫描QR或条形码来加载测量例程。

Easy, Powerful Software

When anXRF coatings instrument使用了,几乎所有操作员的时间都被测量屏幕所消耗。借助FT230上的全新FT连接软件,日立高科技将操作员放在首位,以确保简单的分析。

- 新的智能软件:今天的软件平台通常基于几年前的设计要求,限制和用户偏好。尽管它们包含了几个宝贵的功能,但培训新操作员可能很困难,因为界面已经进行了很多操作,因为这些工具首次开发了。

在过去的二十年中,手机,平板电脑,计算机,电视,汽车甚至烤面包机上的软件已大大推进。借助FT Connect在FT230上,XRF涂料分析仪的软件可以满足现代行业的需求。

- 用户首先来: In contrast to previous software platforms, FT Connect completely inverts the user interface. Rather than having a small view of the part surrounded by buttons, controls, and settings, the FT Connect measurement screen is able to focus on the two most crucial tasks that an operator needs to focus on: setting up a measurement and how to act on the results.

Occupying 60% of the screen, FT Connect has the largest sample view display on the market and it also has extremely flexible lighting controls. The user can regulate dozens of LEDs either as rings, wedge segments, or individually to make sure they have the best possible view.

工厂的预设建议也可以使用,并且可以生成新的定制照明设置以简化未来的测量。

Results are clearly displayed next to the camera view with tools for trend and statistic assessment, generating reports, or exporting results and looking at historical results. Each result card can be easily expanded to view further details about previous measurements for rapid interpretation.

数据处理功能已准备就绪4.0行业。可以以全面的JSON格式或电子表格表格导出结果,以与SCADA,QMS,MES或ERP系统集成。

全球支持以保持用户的启动和运行

在日立,一旦安装了FT230,支持就不会尽快结束。该公司在整个乐器一生中与客户合作,以确保手头上得到全力支持 - 无论是提供额外的培训,技术支持,日常维护,包括预防性维护和认证或维修。

- 专家支持,全球:日立在美国,英国,德国,印度,中国和日本设有办事处,可提供世界领先的技术支持和应用开发能力。日立的全球培训合作伙伴团队是其办公室的一个欢迎补充,因为该团队同样致力于客户满意。

- Remote diagnostics: the FT230 has numerous layers of diagnostics to ensure the XRF is performing as expected. It comes as standard with an instrument health check, has a daily check feature to validate your calibrations before production parts are measured and can run detailed instrument diagnostics.

使用基于云的数据管理和存储解决方案,直接与Hitachi的专家支持团队直接并自动共享所选的诊断数据。这是将数据获取到日立工程师的最快方法。

可以快速评估该仪器,以在现场前确定精确的问题区域。这有助于确保工程师可以访问正确的零件,以使客户尽快启动和运行。

FT230只是涂料行业的许多解决方案之一。Hitachi提供了广泛的专用仪器:用于油漆,阳极氧化和PCB铜厚度的电磁仪,XRF coatings analyzers, handheld XRF for coatings and materials analysis, instruments with extensive capabilities for solutions analysis and thermal analysis instruments for proper materials properties testing.

Take a closer look at Hitachi products and make the switch today.

该信息已从日立高科技分析科学提供的材料中采购,审查和改编。欧洲杯足球竞彩欧洲杯线上买球

有关此消息来源的更多信息,请访问日立高科技分析科学。欧洲杯线上买球