In this interview, Erik Novak, Ph.D., the General Manager at 4D Technology, talks to AZoM about why automotive paint is essential for vehicle manufacturers.

Why is automotive paint essential for vehicle manufacturers?

Paint and finishings are crucial for customer satisfaction and are a way for consumers to project individualized branding through color, make, and model choices. Dissatisfaction with a vehicle’s paint and coating is the number one reason why buyers reject a new purchase on delivery.

它们对于防止车身的腐蚀和腐烂至关重要。良好的装饰使车辆易于洗涤并保持汽车看起来不错,从而使其能够在其寿命中保持其结构完整性。

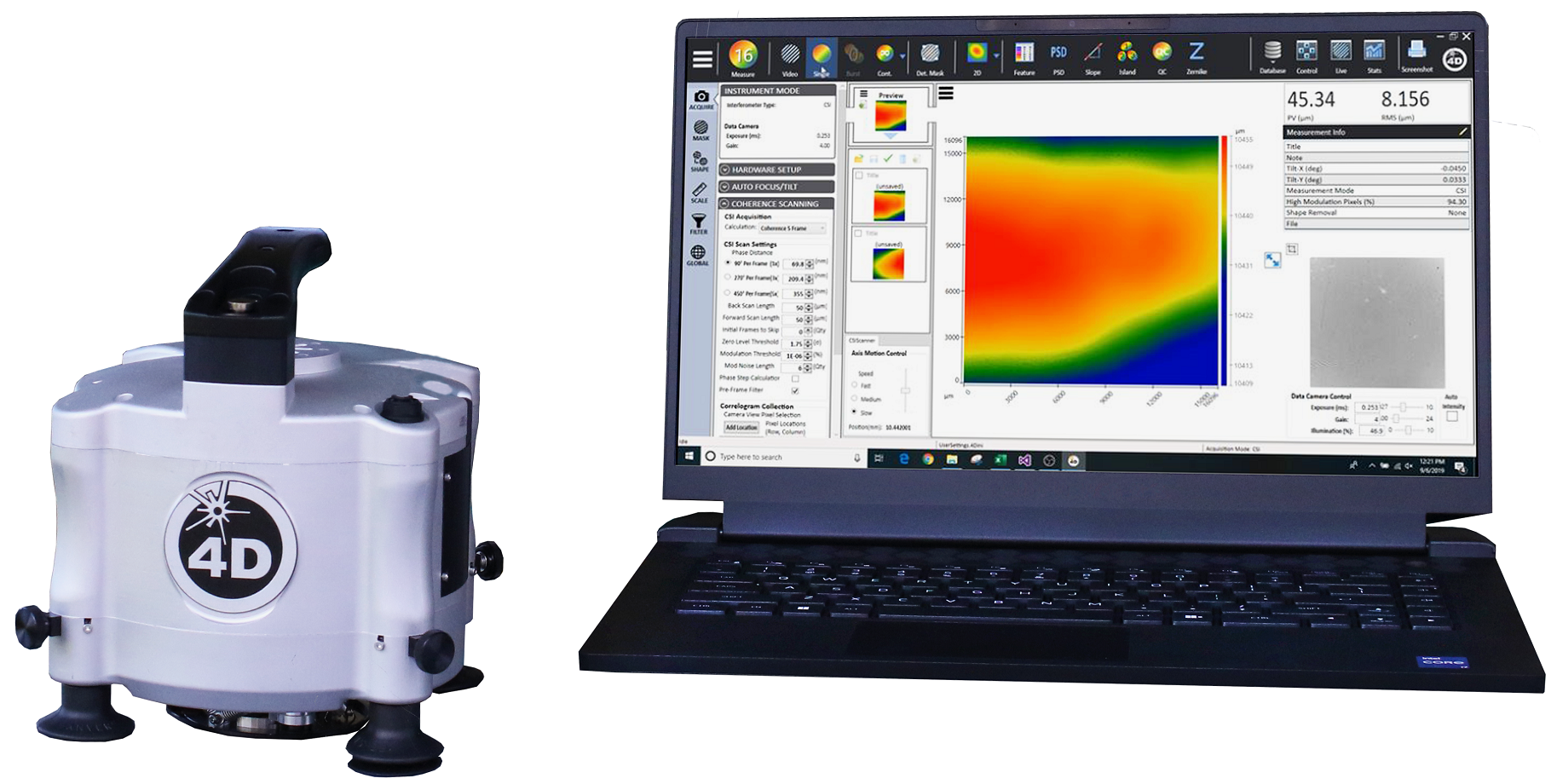

Image Credit: 4D Technology

What percentage of car production costs go into paintwork?

In the assembly plant, a substantial investment is made in the paint shop for equipment and processes, including automated lifts, baths, conveyors, ovens, chemicals, inspections, and rework. These are all necessary to achieve customer satisfaction.Paint and coatings占汽车生产成本的30%,包括设施和能源预算。

How has car manufacturing changed, and how has this impacted the paintwork aspect of the industry?

An ongoing revolution in car manufacturing is ‘lighweighting’ or reducing mass. This comes down to physics. Reducing mass impacts mileage (and electric vehicle range) more than any other engineering process. This means that manufacturers use less steel and more aluminum, rubber, plastic, and carbon fiber parts – even in the bodies.

A steel fender and an aluminum car door, for example, have different surface microstructures and require different finishing techniques. Paint does not adhere to them equally, resulting in a remarkably different visual outcome. Sufficient paint on one might be too much paint on the other.

The same is true for plastics and rubber, which might require different paint formulations than metal, leading to differences in color, gloss, and smoothness that a discerning eye could detect.

什么是新的3D表面测量仪器,其对汽车制造商的优势是什么?

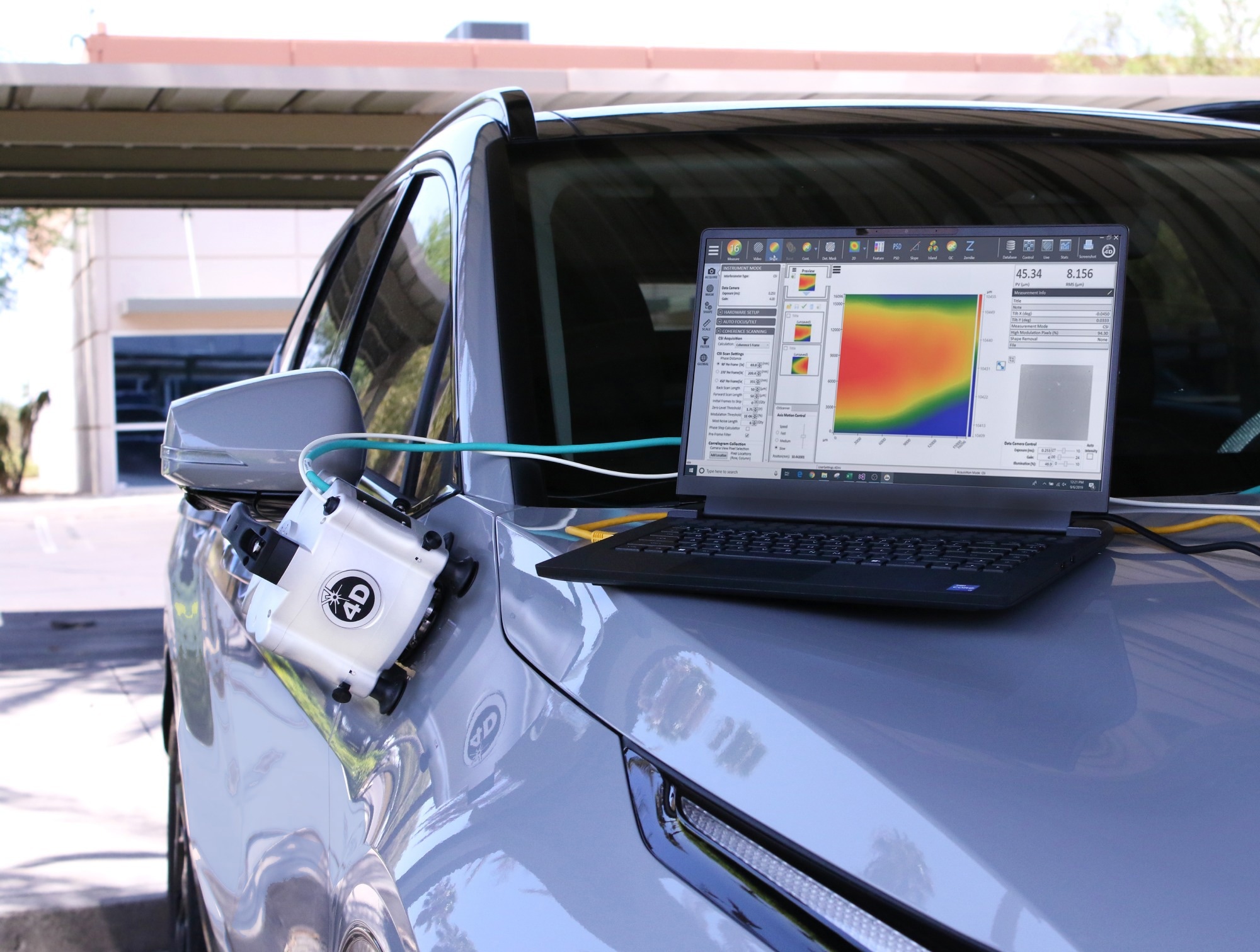

Firstly, the 4D SurfSpec is portable. It can be placed on a car part, a roll of metal, or a molded part – even on vertical surfaces or upside-down. It is a 3D microscope with an extensive field of view that can measure surface roughness using a technique unaffected by shine or color. This makes it possible to measure bare metal, plastic, primed materials, and painted surfaces.

一旦测量,在组装过程中获得的结果可以与更晚和更早的阶段相关联。这是因为在每个阶段都使用相同的技术和传感器,并具有高度准确且可重复的结果。

The measurements determine the three-dimensional surface shape, so they are not impacted by surface grain orientation the way a linear gauge would be. The4D Surfspecgaugeis non-destructive and robust enough to be placed on a car part on the assembly line. It does not need to live in a quiet metrology lab, so there is no need to cut down oversized parts, use witness samples, or interrupt assembly in the evaluation process.

What is this instrument designed to evaluate?

Each step in the assembly process can affect future paint flow and adhesion to the car body. Differences may be seen as the result of the texture of rolled metals, the stress lines that appear after stamping and hemming a part, or the amount of e-coating that different parts are exposed to, right up to the angle, force, and volume of paint sprayed.

Until this instrument was developed, car manufacturers could not accurately predict a painting outcome based on earlier materials and process conditions.

How does this help avoid microstructures in raw materials?

By fingerprinting the process from raw materials to the final coat, auto manufacturers and their suppliers can identify microstructures in raw materials that can affect the finish.

With access to a library of minimum requirements, they can specify the surface parameters required, and confirm on delivery that the materials have the desired microstructure. Certain manufacturer clients have already suggested that their suppliers use the 4D SurfSpec for this purpose.

Image Credit: 4D Technology

Why are microstructures undesirable, and what issues can they cause?

在基板上,需要一定的微度,因为它有助于绘制粘附,流动和光滑度。长达5毫米长的结构,例如滚筒波或折叠铝中的应力线,在光滑,光滑的彩绘表面上,人眼可见。

On these surfaces, they appear as orange peel or roping effects but can be masked in an unpainted surface that has surface roughness, or color changes due to contaminants and heating.

数据需要用带通滤波器过滤,以突出这些结构。这些结构在面积测量值中比在2D轮廓中更容易检测。除了表面的“波浪状”外,在绘画过程中引入并发症引入并发症的另一个功能较小,直径为20 µm,在油漆中产生针孔。

这些可能很难在原始粗糙度数据的“噪音”中发现,如果依靠手写笔配置文件来识别它们,它们很容易通过。

What can auto manufacturers do about parts that have been e-coated or primed?

测量已经被电子涂层或底漆的组装自动车身提供了更多的机会,可以返回在最终涂层期间可能失败的区域。无论表面需要返工还是准备涂层需要修复,如果可以在绘画之前修复整体整体整体,则将更好。

Why is this assessment critical, and what can it help prevent?

If a part needs to be masked, stripped, and spot-repainted, it will inevitably cost time and money. Reworking them is time-consuming and painstaking. Sometimes there is no assurance that the “fix” will also be successful. Correctly assessing the part can help prevent pinholes, drips, runs, orange peel, roping, and haze, all of which are considered undesirable defects in the paint shop.

What defects can the instrument spot in finished coats of paint?

量化缺陷比发现它们更为关键。在16 x 16 mm的视野中,分析软件可以立即计算有多少个针孔。

With 15 nm height resolution, the measurement is extremely sensitive for capturing the structure of orange peel, even if it is undetectable to the human eye. The manufacturing process will benefit from knowing how often a finish is close to failure or rejection.

Why is this instrument ’a first’?

4D Surfspecis the only production-line 3D surface measuring instrument that can fingerprint surfaces across an entire automotive coating process, helping manufacturers and suppliers identify optimal surface conditions before the coating process begins.

It is the only instrument on the market capable of evaluating the entire process, identifying features that lead to paint defects like orange peel, roping, and pinholes. It also offers comprehensive, high-resolution 3D non-contact measurements that are non-destructive and quick, enabling measurement on the production floor.

Finally, it can be used by auto manufacturers and their material suppliers to ensure that production parts produce a consistent, high-quality finish.

How do customers benefit from the prep-to-finish utility?

Firstly, it translates to increased consistency and an excellent final product with less rework. This is because having a process fingerprint inevitably leads to a more consistent, less defect-prone result. The capacity to check each stage means clients can call for a part’s remediation or scrap before committing to the finishing and “value-adding” steps, saving work and materials.

Quantifying the pass-through effects of different starting conditions will mean that manufacturers can specify desirable surface parameters, and suppliers can test in advance to avoid rejection. Everyone in the supply chain gains confidence.

When process steps like folding, hemming, and welding can impact surfaces and result in poor coating on a piece of sheet metal, inspecting those “trouble areas” with pass-fail specifications can prevent a problematic part from being assembled into a finished body.

工程工程师可以通过测量最终外套来检测变更时间的趋势,其中3D测量结果进入结果数据库。这是定量记录随附的放心的另一个方面:用户可以参考任何以前的测量值,并确认该缺陷在该阶段不存在,建立信任并改善根本原因分析研究。

该信息已从4D技术提供的材料中采购,审查和改编。欧洲杯足球竞彩

有关此消息来源的更多信息,请访问4D技术。

免责声明:此处表达的观点是受访者的观点,不一定代表本网站的所有者和运营商Azom.com Limited(T/A)Azonetwork的观点。此免责声明构成了Terms and Conditionsof use of this website.