在这次采访中,Freeman Technology的运营总监Jamie Clayton与Azomaterials讨论了粉末测试对添加剂制造的重要性。欧洲杯足球竞彩

What is the importance of powder testing for additive manufacturing (AM)?

相关测试AM粉末原料的能力直接支持关键行业挑战,例如有效的供应链管理,过程优化,新的原料开发以及粉末回收/再使用。我们的意思相关的测试正在生成与过程中的性能相关的结果和/或打印质量可靠,灵敏。测试结果,可以预测特定应用的粉末性能。替代方法是过度依赖印刷试验,一种“印刷和查看”方法。但这很耗时,昂贵,而且对于新材料通常不可行。欧洲杯足球竞彩

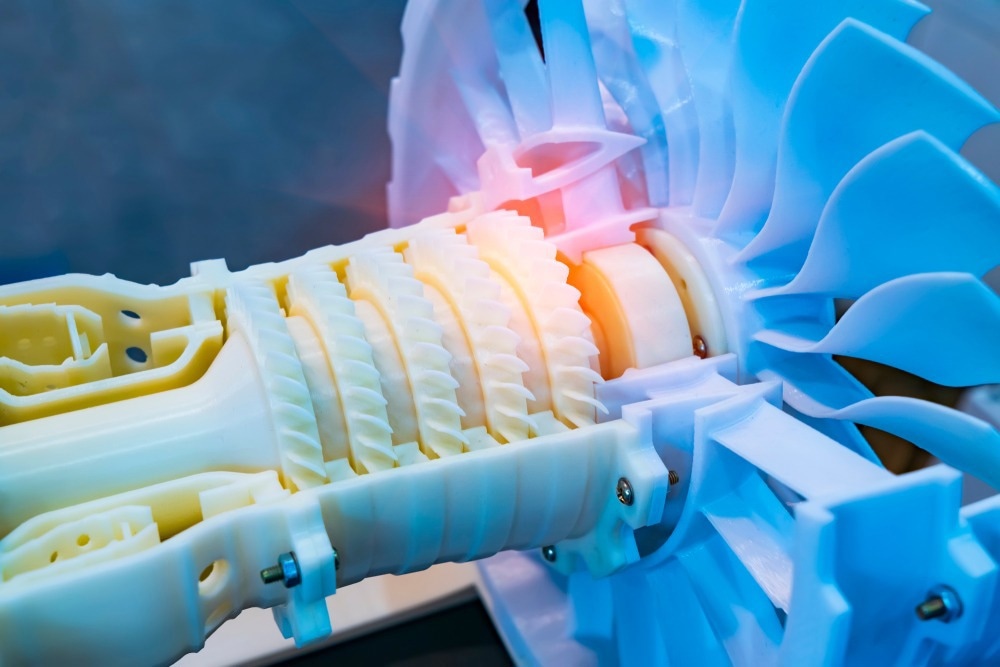

Image Credit: ShutterStock/Nordroden

Because of the industrial significance of powder-based AM processes such as binder jetting and powder bed fusion, AM processors have long recognised this need for effective powder characterisation. Pioneers have invested heavily in developing appropriate specifications, following a trajectory that mirrors progress in other powder processing industries. The earliest specifications centered solely on particle properties, but bulk powder properties were added soon after.

Particle properties such as size and morphology are relevant and easy to measure but in isolation, they are rarely sufficient to differentiate fresh AM feedstocks and/or the impact of recycling. AM processes are exacting in terms of flowability, spreadability, packing behaviour, response to heat, and of course, chemistry. Leaving chemistry aside these behaviours can be related to particle size and morphology, a classic example being that larger, more spherical powders tend to flow more easily than finer, irregular analogues but not to the extent that we can predict bulk powder behaviours from assessing particle properties. Measurement is the pragmatic alternative. With appropriate powder testing, we can relevantly quantify defining bulk powder behaviours and use them to help predict both printability and print quality.

Are we able to predict printability from powder properties? And if so, how?

对于任何新鲜或再生AM粉末来说,可打印性是至关重要的第一障碍。通过可打印性,我们的意思是易于处理。我们希望回答这个问题 - 我可以以可接受的速度打印,并且没有频繁的打印机障碍?

For some, this issue is synonymous with just one powder behaviour – spreadability. In both binder jetting and powder bed fusion, the spreading of powders to uniform layers just tens of microns thick is a critical step. A focus on spreadability is therefore warranted. However, in these processes, powders must also dispense freely from feed hoppers, prior to spreading, and pack efficiently and rapidly into uniform layers, to realise high throughput printing. Focusing on spreadability to the exclusion of all other properties is therefore inadvisable.

Image Credit: ShutterStock/asharkyu

还倾向于使用术语互换使用术语和可扩展性。有很多方法可以测量流动性,可扩展性和流动性是相关的,但是它们是不同的行为,自由流动的粉末不一定在强迫条件下很容易扩散,这可能是由重新配置所应用的。当评估粉末流动性的替代度量时,批判性评估相关性的主张至关重要。

在此背景下,我强调了使用AM适用性(AMS)预测可打印性的有前途的工作。

Ecole de Technologie Superieure的研究人员1比较了激光粉末融合打印机中TI-6AL-4V的三个商业供应的性能。仔细选择了这些供应,以实现对粒径和形状的影响的独立研究。然后,使用FT4粉末颗粒®进行散装粉末测量,以更相关地了解大小和形状的影响,并查看是否可以预测打印性能。七个散装粉末特性被确定为相关的:基本的流动能量(BFE),特定能量和充气能量,它们都是动态粉末性能,可压缩性,渗透率,散装密度和凝聚力,即剪切特性。所有这些参数的归一化值被合并为AMS因子,然后用来对三个粉末的性能进行排名。印刷试验证实了该排名的有效性,其较低的AMS值与具有更好的加工性的粉末安全相关。更具体地说,具有较低AMS值的粉末,可以用更深的层打印,从而增加潜在的吞吐量。

This approach of using an AMS factor was subsequently adopted by researchers from Oerlikon to assess the processability of blends for原位在激光粉床融合过程中合金2。该小组还得出结论,AMS因素可以提供“可靠的加工指标”,从而增加了将多个相关属性组合以进行健壮评估的概念。这些研究与选择以定义AMS因子的确切参数不同的参数之间的奇偶度有所不同。值得注意的一个关键点是,每种情况中都包含动态,剪切和散装特性,突出了FT4粉末变性仪的潜在值,从而结合了所有必需的功能。

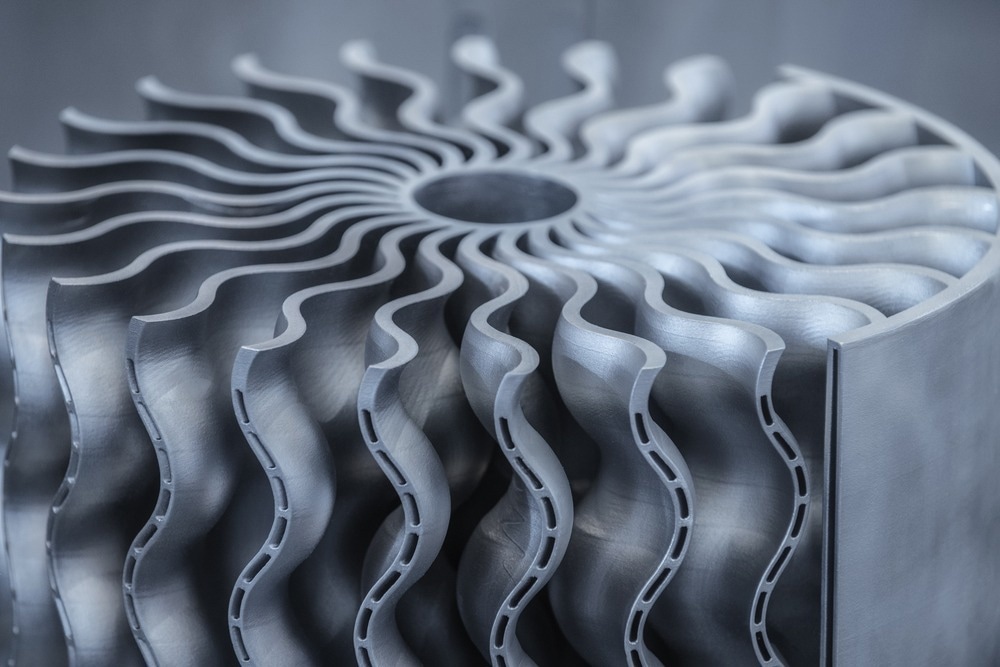

FT4粉状流变仪

Image Credit: Freeman Technology

总而言之,我建议我们可以通过合理的成功来预测可打印性,如果我们使用适当的属性集合来捕获所有相关行为。结合动态,散装和剪切特性在这方面已被证明是成功的,尽管仍然可以通过不同参数的不等加权来完善不同应用和过程的方法。

Are we able to predict print quality from powder properties? Can you point to good examples of success?

Beyond the question of whether it will be possible to print with a specific powder lies the bigger issue of how to control print quality, and how to manipulate the properties of the printed component. We’re moving towards being able to predict print quality but it’s harder than predicting printability and multi-faceted powder testing is certainly required.

在粉末中,AM均匀层沉积是良好的打印质量的基础,在加工性和打印质量之间建立了直接联系。但是,散装粉末特性也可能影响沉积后的过程。例如,烧结和熔化行为受床传热的影响,而粘合剂喷射是粘合剂穿透的类似问题。通常,目标是生产具有理想的机械性能组合(通常包括高强度)的组件。将这些目标与对相关粉末特性的早期讨论相关联,突显了由大量参数(例如密度,渗透性和可压缩性)量化的粒子堆积行为的重要性。有效的填料可以最大程度地减少床上的空气口袋,并扩大了成品中融合缺陷的风险,但同时提高了传热效率,可能使得更难精确地施加热量以实现良好的尺寸准确性。

尽管这种额外的复杂性使预测印刷质量变得困难,但越来越多的成功证据。

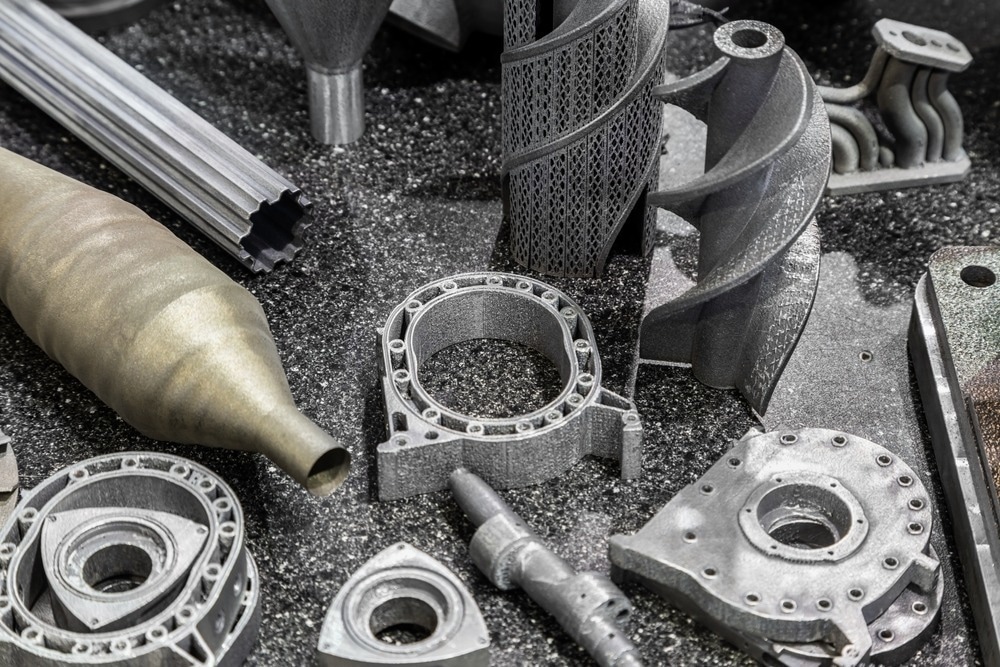

图片来源:shutterstock/olegdoroshin

例如,较低的AMS因素已与优越的印刷特性牢固地联系在一起,并强调了这种方法的优点1。Multi-faceted testing is also used to establish a specification for Inconel powders for laser metal deposition applications in the aerospace industry3。在这里,建议是将动态流属性BFE添加到基于粒径和霍尔流量指数的现有规范中,以支持能够提供所需打印质量的粉末原料的可靠选择。切换到聚合物,特别是聚酰胺,Demontfort大学的研究人员的研究4在选择性激光烧结试验中,BFE与机械性能(例如拉伸强度和表面硬度)之间显示出很强的相关性。同时,维度精度/一致性与粒子堆积指标之间的反相关关系突出了需要评估和优化多个粉末特性以实现印刷质量目标的需求。

Is the industry maximising its use of powder testing yet?

整个行业可能尚未从粉末测试中提取那么多价值,但是肯定有一种改变的胃口,有些真正的好习惯可以指向那些引导道路的人。

For example, ExOne, a global leader in binder jetting has had robust metal powder specifications for printability in place for several years now. They’ve used the FT4 Powder Rheometer to develop specifications that include dynamic (Stability Index and Flow Rate Index), shear (Cohesion and Wall Friction Angle), and bulk powder properties (Permeability and Compressibility). Using them the company can assess printability prior to a trial, for an alternative feedstock, a customer material, or a feedstock in development. This accelerates progress and is particularly helpful when a material is in short supply.

最近,我们还听到Evonik的专家的消息,他们同样使用FT4来表征用于3D打印的聚合物粉末。他们在开发新聚合物粉末的开发中节省了大约两个月的打印机时间,这是因为能够根据粉末测试缩小多达500种配方的领域。这是一个巨大的节省,不仅在时间方面,而且从减少废物的角度来看,这是一个越来越重要的目标。

Companies such as these that invest in establishing robust specifications have a real advantage when it comes to speed of feedstock and process optimisation for a specific application, and also when establishing reliable supply chains. The ability to differentiate alternative supplies sensitively and relevantly is crucial when it comes to identifying the most cost-effective option.

AM内的粉末测试有任何提示或预测吗?

展望未来,AM中的粉末测试似乎会变得更加标准化。我坚信,由于已经证明的成功,而且由于它似乎很明智,因此多面测试和规范会留在这里。仅使用一个或两个指标来捕获我们对AM的粉末期望的复杂行为,或者实际上具有低灵敏度指标是不现实的。我的看法是,技术和属性将根据共识和成功证据的重量逐渐赢得规格。近年来,我们对关键行为(例如传播性)的理解大大提高,但最终,我们为行业提供了专门的工具,用于这样的特定行为。随着行业不断增长,更安全的预测的价值肯定会值得。

图片来源:Shutterstock/Sergii Chernov

我建议任何正在进行的人都希望促进粉末测试,以寻找明确的证据,即一种方法可以测量与性能指标相关的属性。对我而言,最好的研究是那些粉末性能的影响直接到真实,经济重要性的参数的那些研究 - 检测粉末会阻止打印机之前阻止粉末的能力,以通过使用较厚的层来增加吞吐量,降低成品组件的表面粗糙度或增加其拉伸强度。相反,简单的试验表明,例如,流动性度量和对“可扩展性”的衡量标准之间的相关性仍然太普遍,而且引人注目。

最后,我想说,不要低估相关粉末测试的价值。能够快速可靠地选择原料,或者在没有无尽的印刷试验的情况下优化回收策略,可以带来可观的经济利益,并在这个令人着迷的,仍在不断发展的行业中显着提高竞争力。

Further reading

- Download添加剂制造的粉末流程测试深入研究该主题,包括大量案例研究数据或有关AMS因素的更多信息,请阅读我们应用注释。

- 提供了与Evonik专家有关粉末测试主题的圆桌讨论的文章这里。

关于杰米·克莱顿

Jamie Clayton is Operations Director at powder characterisation company Freeman Technology, based at the company’s headquarters in Tewkesbury, UK. He graduated from the University of Sheffield with a degree in Control Engineering and is responsible for the overall management of company activities, including the R&D, production, sales, and customer support teams.

During his time with the company, Jamie has worked as a mentor with several academic groups and is an active member of ASTM F42. Jamie is also a regular contributor to conferences and workshops on the topic of powder rheology and works closely with clients on the application of the company’s technology.

关于弗里曼技术

弗里曼技术specialises in systems for measuring the flow properties of powders and has over 15 years’ experience in powder flow and powder characterisation. Expert teams provide comprehensive support alongside the company’s range of products.

在世界各地的各种行业中,系统都安装在世界各地。他们提供的数据可以最大程度地提高过程和产品理解,加速研发和制定成功商业化,并支持粉末过程的长期优化。

Micromeritics公司Freeman Technology总部位于英国格洛斯特郡,拥有主要全球领土的运营和分销伙伴。

2007年,该公司获得了女王创新企业奖,并在2012年获得了女王国际贸易企业奖。www.freemantech.co.uk

References

- S.E.Brika等人'粒子形态和尺寸分布对TI-6AL-4V合金的粉末流动性和激光粉末床融合的影响。添加剂制造31(2020)100929

- M.S. Knieps et al ‘In situ alloying in powder bed fusion: The role of powder morphology’Mat Sci和Eng A, 807 (2021) 140849

- L. Markusson的“添加剂制造过程的粉末特征”项目。发布于2017年。可在以下查看:https://www.diva-portal.org/smash/get/diva2:1084670/fulltext01.pdf

- R. Baserinia等人“将聚酰胺粉末流动性与制造零件的机械性能相关联”粉末技术398 (2022) 117147

免责声明:此处表达的观点是受访者的观点,不一定代表本网站的所有者和运营商Azom.com Limited(T/A)Azonetwork的观点。此免责声明构成了条款和条件使用此网站。