由...赞助TofwerkDec 8 2022由艾米丽·马吉(Emily Magee)审查

半导体制造设施中空气传播分子污染物(AMC)的敏感和快速检测对于生产质量和效率至关重要。Fabs有可能接收数百个独立的过程,这些过程充当污染源,例如泄漏,通风系统,设备故障和人类排放。

Image Credit: TOFWERK

AMCScomprise a range of chemical compound classes that are not extensively quantified by traditional monitoring methods. Since nodes continue to progress to smaller dimensions, the existence of AMCs at trace concentrations (<10 ppt) has a greater impact on wafer defects, leading to yield loss.

A considerable variation in physicochemical properties is found in AMC classes, uniquely reacting or interacting with surfaces or other compounds.

由于AMC组成的复杂性,现代监测系统应广泛量化涵盖多种化学功能的广泛化合物以及具有足够灵敏度和速度的一系列蒸气压。

Using real-time chemical ionization time-of-flight mass spectrometry integrated with proprietary quick polarity and reagent ion switching, ClearFab ABC tracks assistance up to six chemical ionization chemistries.

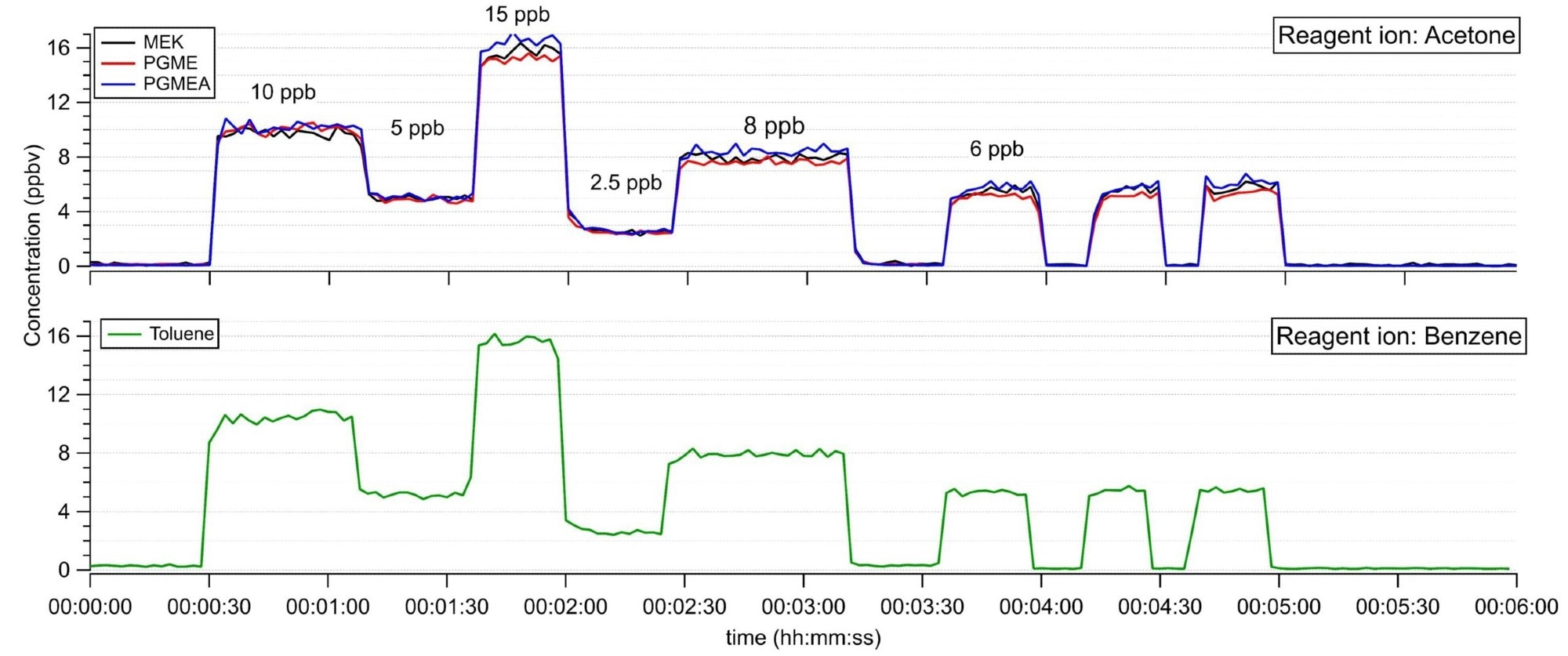

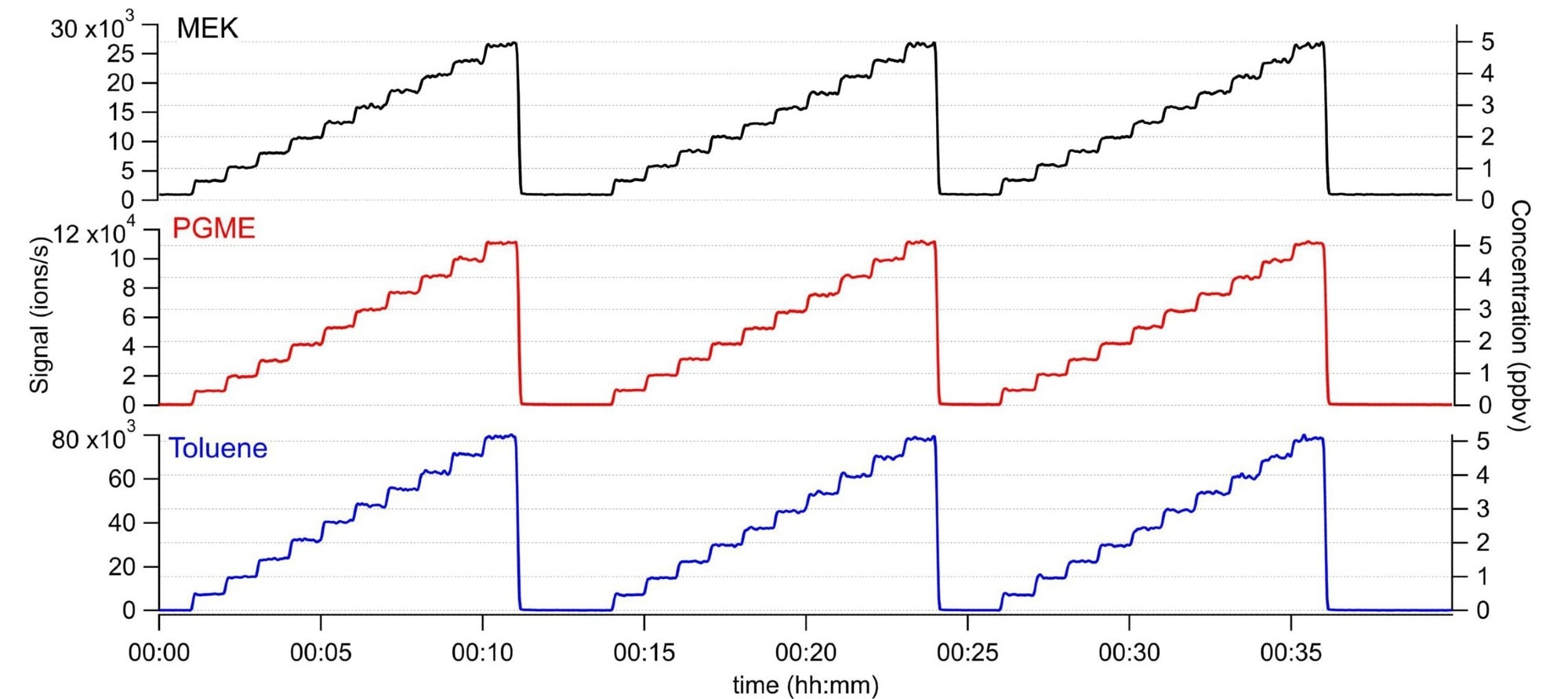

这使得可以检测多个AMC类,其周期时间低于两秒钟。图1说明了ABC监视配置的恢复和响应时间。

图1。Response and recovery time of a ClearFab AMC Monitor. Labels in the plot show target concentrations while the Y-axis shows the measured concentration of selected compounds. The upper plot shows the concentration of MEK, PGME, and PGMEA measured with one chemical ionization chemistry, while the lower plot shows the simultaneous measurement of toluene with another chemical ionization channel chemistry。Image Credit: TOFWERK

利用软电离,AMC成分通过微不足道的碎片化来量化,从而可以进行强大的数据定量和直接的质谱解释。

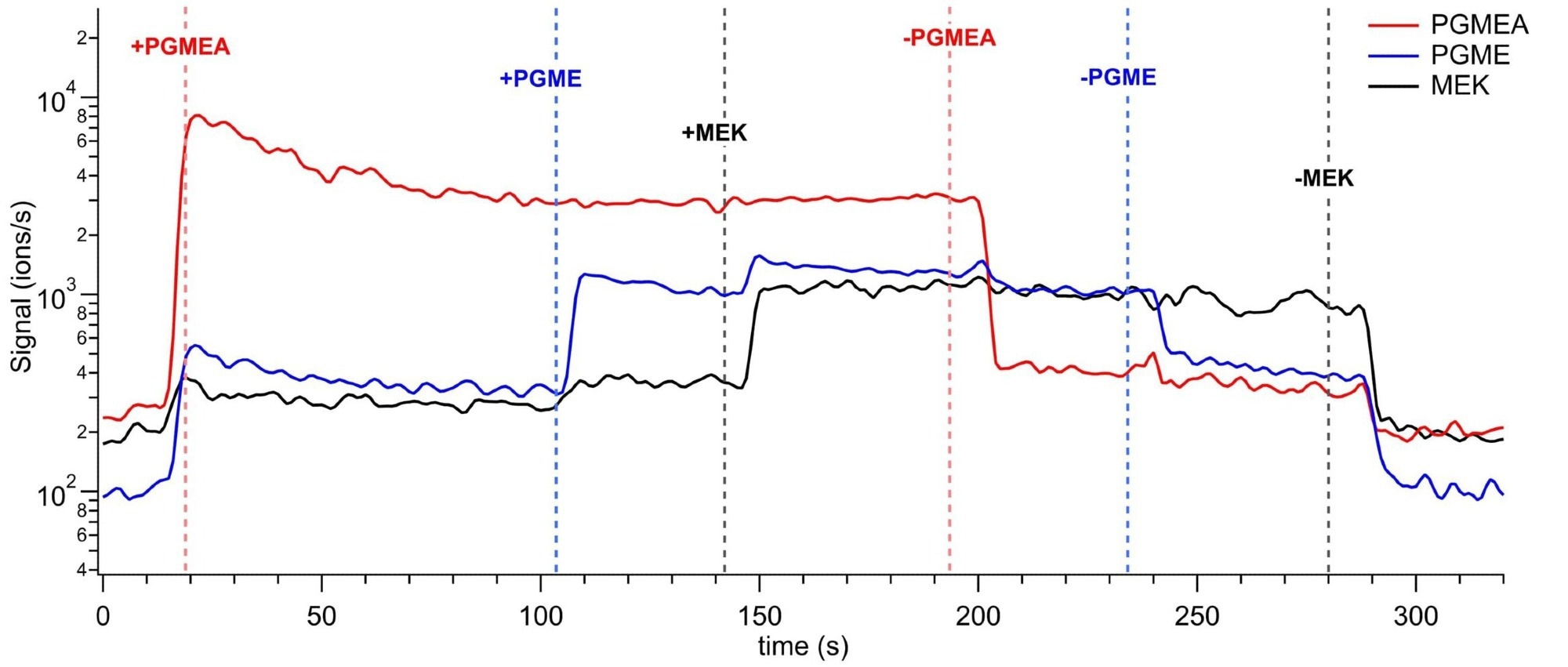

由于碎裂的结果,化合物,例如丙烯乙二醇甲基醚(PGME,107-98-2),丙烯乙二醇甲基乙酸乙酸酯(PGMEA,108-65-6)和甲基乙基酮(Mek,78-93--93--93--93--93--93--93--93--93--3)很难与传统AMC监视器区分开。

Figure 2 presents the sequential measurement and elimination of such compounds to illustrate the efficacy of the fragmentation-free detection offered by the soft ionization of the monitor.

图2。PGMEA,PGME和MEK的顺序测量和去除,证明了这些有挑战性的化合物的检测而不破碎。Image Credit: TOFWERK

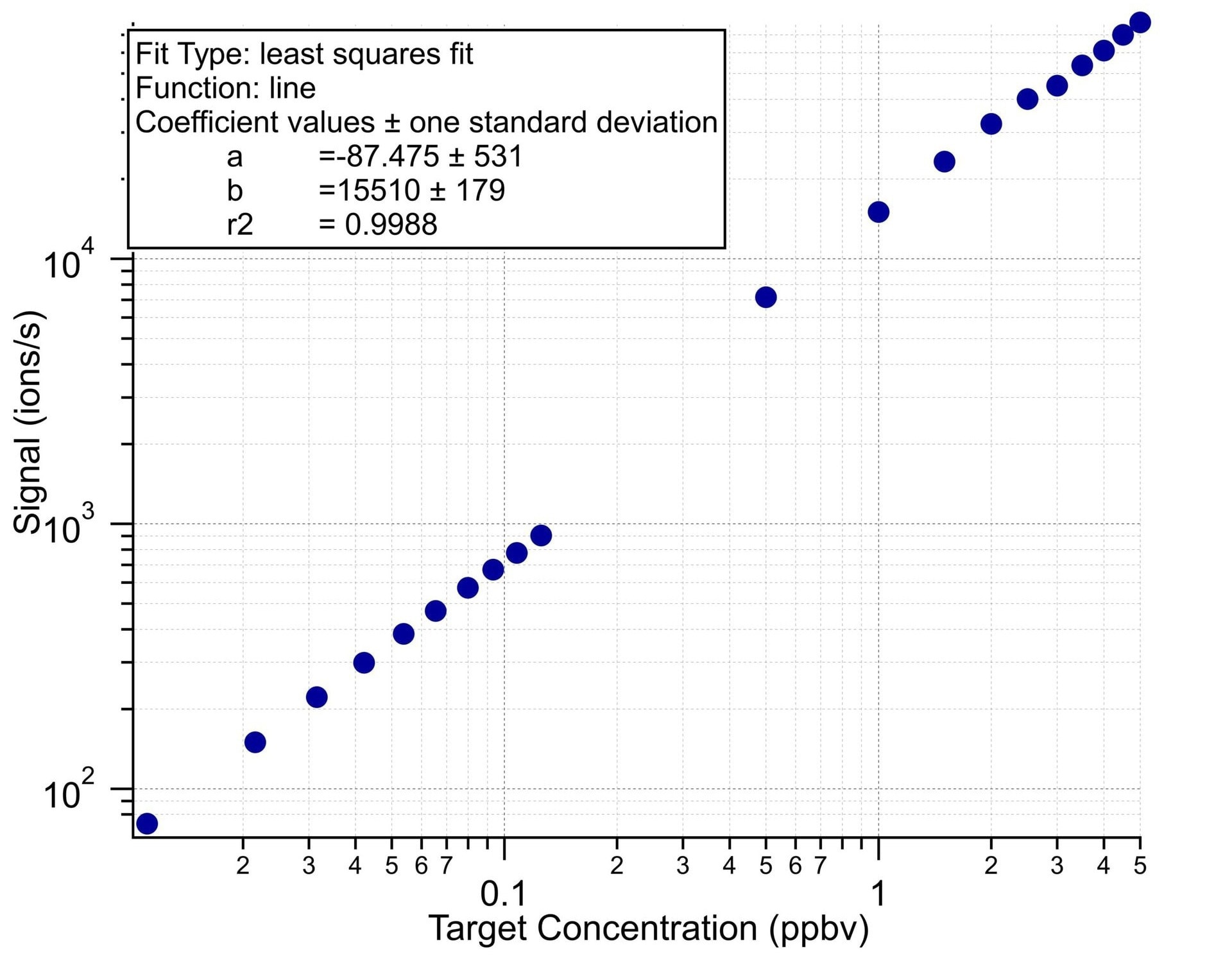

Clearfab AMC监视器offer precise detection of single-digit, part-per-trillion concentrations in real-time, allowing bigger contamination control and detection than traditional technologies. Select limits of detection (LODs) offered by the ABC configuration are presented in Table 1, while coverage linearity is shown in Figures 3 and 4.

表格1。Typical LODs for relevant semiconductor manufacturing compounds with a ClearFab AMC Monitor configured for the monitoring of acids (corrosives), bases, and condensables. Source: TOFWERK

| Compound Name |

CAS |

分子 |

2s LOD (ppbv) |

1min LOD (ppbv) |

| 丙二醇甲基乙酸乙酯(PGMEA) |

108-65-6 |

C6H12o3 |

0.0065 |

0.0012 |

| Propylene glycol methyl ether (PGME) |

107-98-2 |

C4H10o2 |

0.052 |

0.0094 |

| 甲基乙酮(MEK) |

78-93-3 |

C4H8o |

0.421 |

0.075 |

| Ethyl Acetate (EA) |

141-78-6 |

C4H8o2 |

0.104 |

0.019 |

| 环戊烷 |

287-92-3 |

C5H10 |

0.132 |

0.023 |

| 丙酮 |

67-64-1 |

C3H6o |

0.002 |

0.0009 |

| 甲苯 |

108-88-3 |

C7H8 |

0.012 |

0.003 |

| Ammonia |

7664-41-7 |

NH3 |

0.408 |

0.072 |

| Hydrogen fluoride |

7664-39-3 |

HF |

0.011 |

0.0002 |

| Hydrochloric acid |

132228-87-6 |

HCl |

0.526 |

0.095 |

| 硝酸 |

7697-37-2 |

hno3 |

0.0072 |

0.0013 |

| Chlorine |

7782-50-5 |

Cl2 |

0.001 |

0.0002 |

图3。甲苯的线性覆盖范围。Image Credit: TOFWERK

图4。为了证明可重复性,准确性和时间响应,提出了增加浓度的MEK,PGME和甲苯的三个序列。左轴显示了测量的信号,而右轴显示了测得的浓度。The compounds were measured after dilution from a calibration cylinder with a total of 12 compounds, making an overall VOC concentration of ~1200 ppb。Image Credit: TOFWERK

已对ClearFab AMC监视器进行了各种FAB应用的评估,例如洁净室监测,材料瓦解,泄漏检测和FOUP质量控制。

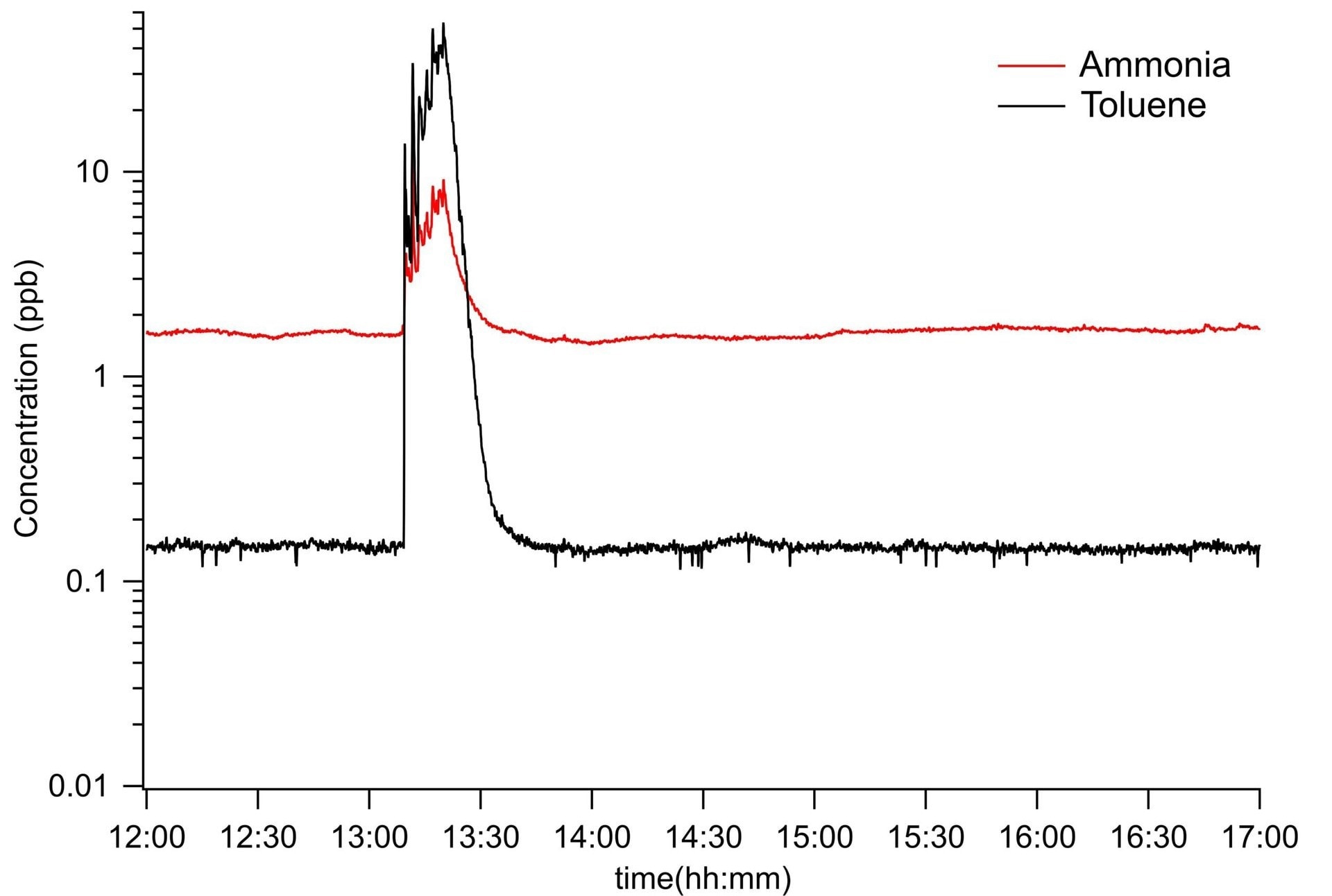

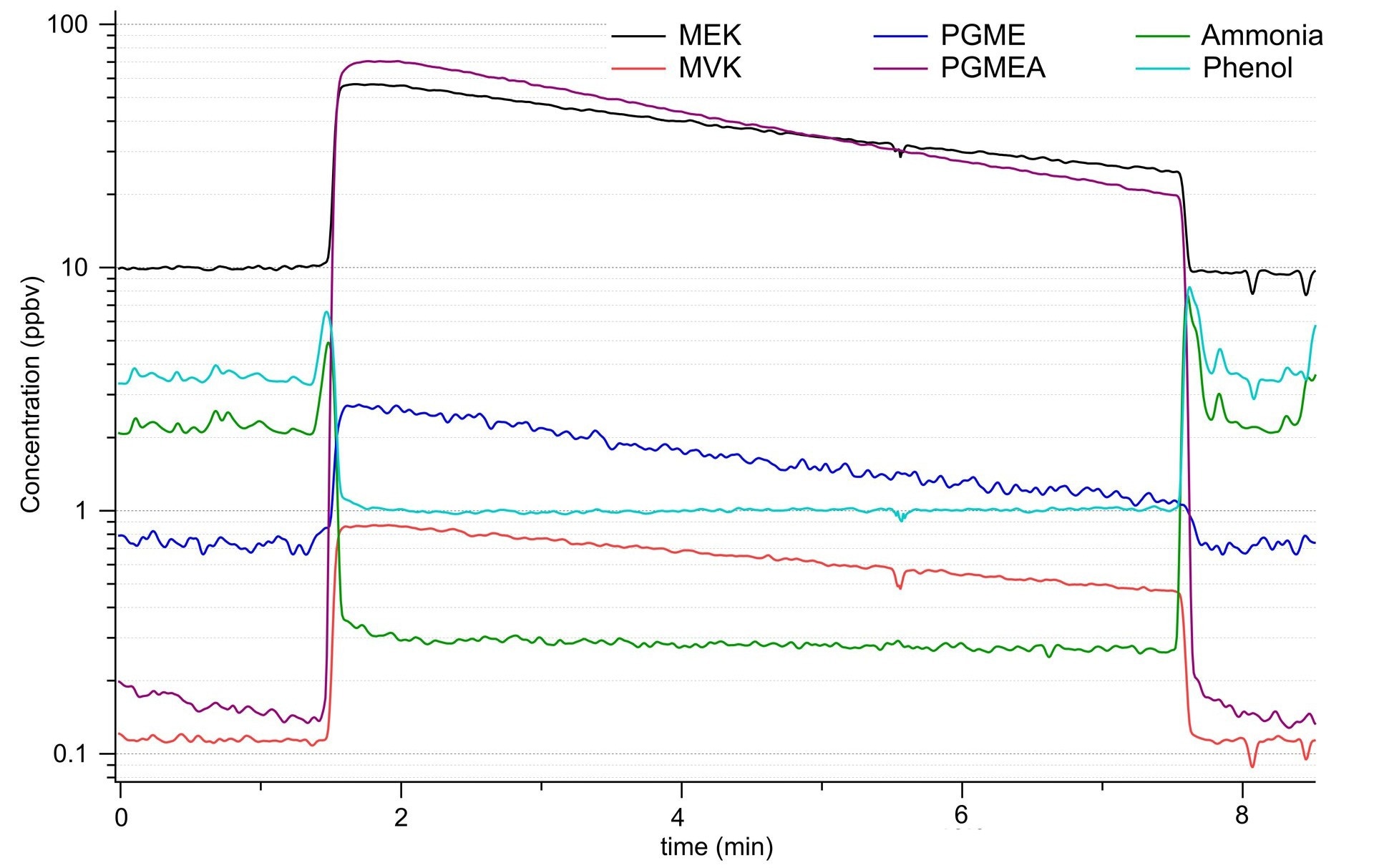

图5显示了一个清洁室事件,其中检测到氨和甲苯的短暂泄漏。图6给出了ISO 5微技术评估的过程瓦解测量。

图5。在ISO 5精细化学清洁室中检测到的氨和甲苯泄漏。Image Credit: TOFWERK

图6。ISO 5微技术清洁室中的材料瓦解。用CDA清除材料,并直接由VOCUS ABC监视器测量。Each time series shows simultaneous compound measurements with 3 different ionization chemistries for comprehensive AMC coverage。Image Credit: TOFWERK

结论

Clearfab AMC监视器描绘了污染控制和监测方面的大量进展,可提供影响生产效率和质量的分子类别的同时,快速和敏感的检测。

Performing complete measurement cycles below two seconds, and outstanding time response, ClearFab AMC Monitors offer a solution to contamination difficulties experienced across semiconductor fabrication processes and surroundings.

此信息已从Tofwerk提供的材料中采购,审查和改编。欧洲杯足球竞彩

For more information on this source, please visitTofwerk。