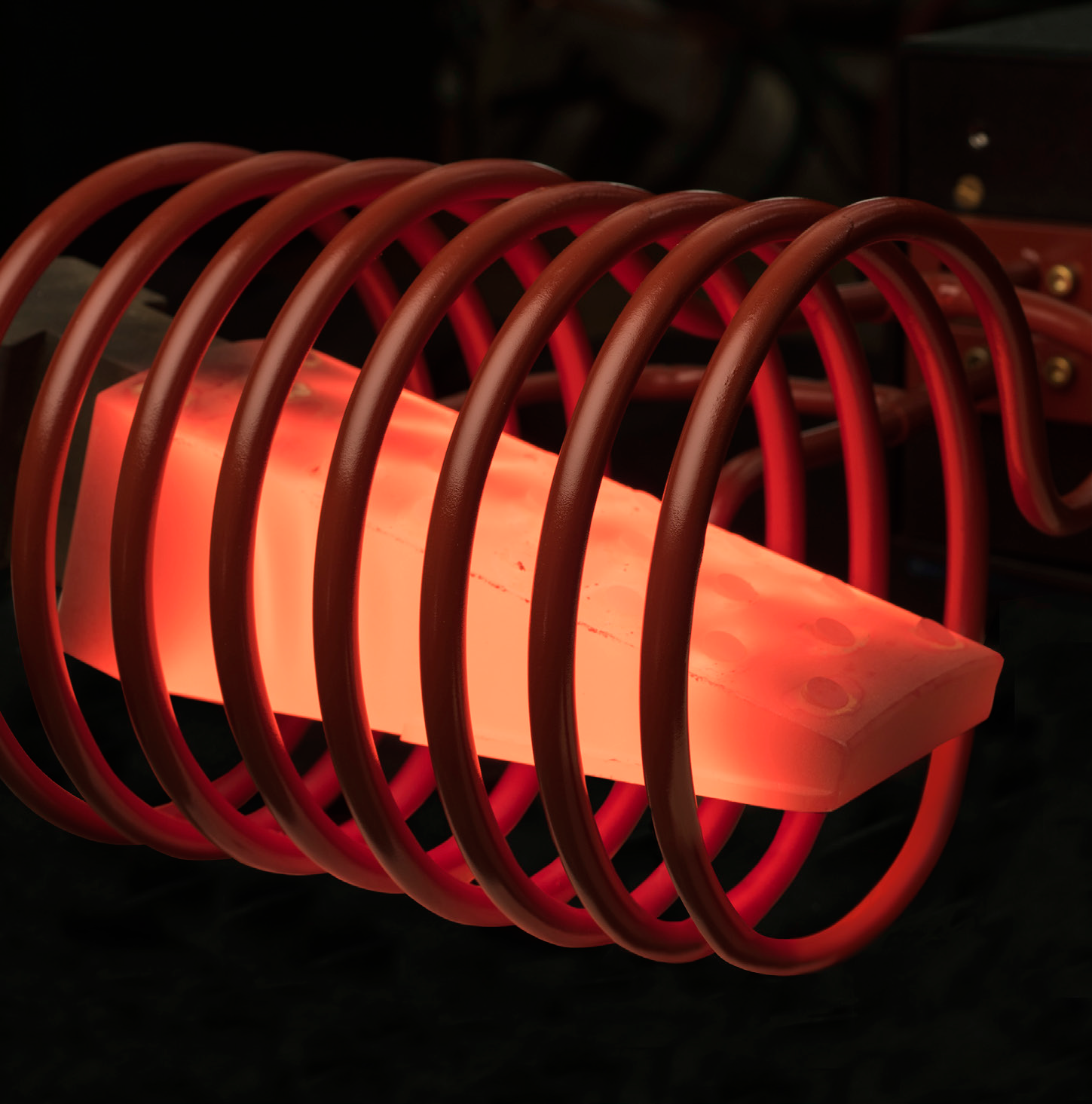

Induction heating is a non-contact method for the rapid, efficient, precise, and repeatable heating of metals or other electrically conductive materials. An induction heating system comprises a power supply that converts line power to an alternating current. This current is guided to a workhead and work coil, generating an electromagnetic field within the coil.

Image Credit: Ambrell Induction Heating Solutions

该工件放在该字段诱导电流的线圈中,在工件中产生热量。水冷的线圈很酷,可以触摸,并放置在工件周围或附近。它不会触及工件,并且热量是由工件中流动的诱导电流产生的。

该工件可以由金属制成,例如钢,铜,铝,黄铜或半导体,例如碳,石墨或碳化硅。通过使用电导引起器(通常是石墨欧洲杯足球竞彩),将非导电材料(例如塑料或玻璃)加热。

虽然诱导供暖已经存在了一段时间,并且绝不是一个新概念,但它是一种绿色技术。它不依赖化石燃料,也不造成任何危险排放或二氧化碳(CO)2).

与gas heating systems, induction offers a cleaner, safer, and more comfortable work environment. When compared to torch heating, induction is flameless, meaning less heat is introduced into the workplace.

Image Credit: Ambrell Induction Heating Solutions

是什么使感应成为绿色技术?

Induction heating is better for both employees and the environment. In addition to the environmental benefits, induction heating provides a series of benefits to employees and businesses, as it prevents smoke, waste heat, noxious emissions, and loud noise. Numerous emission-producing processes can be converted to induction heating, such as:

- 火焰泡沫

- 火焰硬化

- 火焰熔化

- 火焰预热

- Flame shrink fitting

- Gas-fired oven heating

- 加入的焊接火把

Image Credit: Ambrell Induction Heating Solutions

Image Credit: Ambrell Induction Heating Solutions

Induction Heating is a Safer Technology

Besides improving air quality, induction heating also offers many other key employee safety benefits, including:

- 没有紫外线(UV)暴露:与火焰加热不同,诱导不会将紫外线释放到环境中。这样可以防止员工使用火焰加热来源可能发生的紫外线损伤的风险。还需要考虑安全要求,例如员工培训,个人防护设备,适当的安装,标牌和锁定程序,以帮助降低风险。2020欧洲杯下注官网

- 降低接触风险烧伤的风险:由于仅通过诱导加热了工件的特定部分,因此热区有限,可以减少员工接触。结果,与气体加热烤箱或排气系统外部相比,接触烧伤的风险大大降低。

- 零爆炸气:感应使用电力作为能源。这消除了处理高压爆炸气体的需求。通常,这些气体是在炎热的拥挤环境中运输的,这会增加灾难性衰竭的风险。

诱导加热更有效

Induction is an energy-efficient heating process that converts 70-90% of the consumed energy into useful heat. In contrast to electric ovens, which are typically only 45% energy efficient, the overall efficiency of induction heating is up to two times greater.

Moreover, gas oven efficiency is only around 25-30% energy efficient, which comparatively makes induction three times more efficient, especially considering that start-up and shutdown heat losses are eliminated as induction requires no warm-up or cool-down cycle.

The repeatability and consistency of theinduction heating processmake it highly compatible with energy-efficient automated systems.

Image Credit: Ambrell Induction Heating Solutions

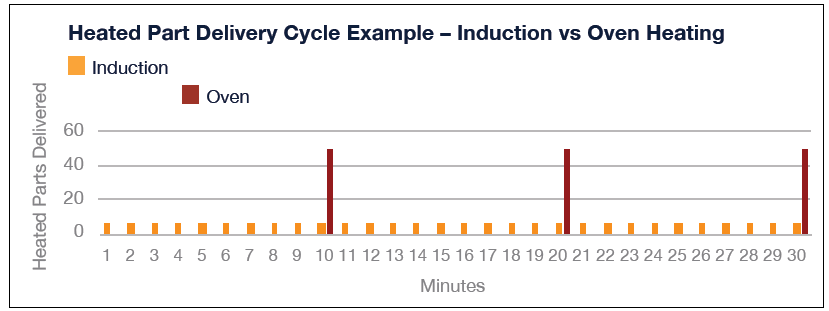

感应供应比烤箱加热更一致的输出

Image Credit: Ambrell Induction Heating Solutions

The application of constant flow induction heating leads to a considerable efficiency improvement when compared to batch oven heating. Induction heating eliminates losses in both energy and time due to oven loading and unloading.

传递一致的零件流,感应支持以后的制造过程中需要加热零件的关键阶段。这增加了周期的总体效率,因为当零件的热量损失达到下一步时会大大减少。这些节省不仅在生产效率方面实现了,而且总体上可以更好地利用加热能力。

Image Credit: Ambrell Induction Heating Solutions

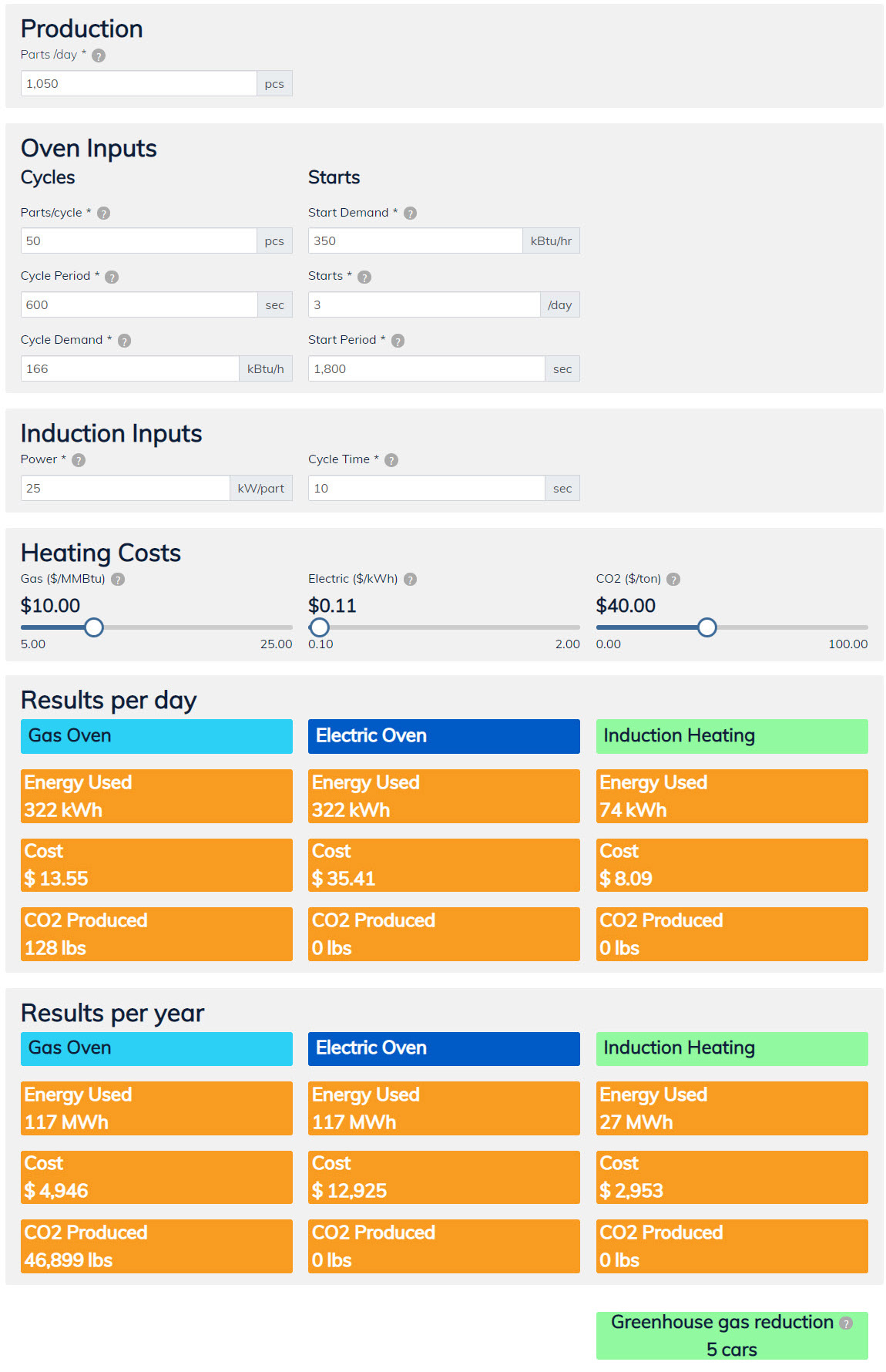

感应与燃气烤箱具有成本效益

当使用烤箱开关的客户进行感应时,环境影响很大。给定下图中显示的输入,induction heating节省128磅的CO2per day and over 46,899 pounds on an annual basis. This is equivalent to taking five internal combustion engine cars off the street.

Image Credit: Ambrell Induction Heating Solutions

与燃气烤箱相比,感应加热可节省大量成本,而与电烤箱相比,差异通常更大。成本变量取决于本地费率;因此,建议使用Ambrell的能量计算器将当前速率应用于可能使用诱导的位置。

Due to the direct transfer of energy to the work piece, induction heating wastes little heat resulting in significant energy savings.

Image Credit: Ambrell Induction Heating Solutions

在这里阅读其余的小册子

在这里阅读其余的小册子

This information has been sourced, reviewed and adapted from materials provided by Ambrell Induction Heating Solutions.

For more information on this source, please visitAmbrell感应加热溶液。