The popular technical ceramic sialon (Si-Al-O-N) is often used in refractory applications, providing enhanced thermomechanical capabilities over traditional industry materials such as alumina (Al2O3) and zirconia (ZrO2). Sialon ceramics have an incomparable balance of thermal and mechanical properties, making them unique. This includes superior thermal shock resistance and mechanical integrity in temperature up to 1400 °C (2552 °F).

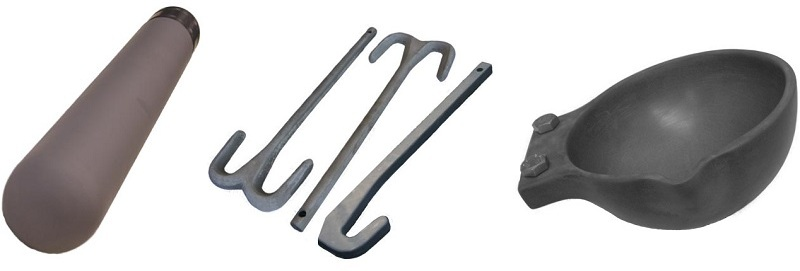

Image Credit: International Syalons

Thermal Expansion Coefficient

Athermal expansion coefficientis a well-established key principle that all solid materials have different properties when exposed to variations in temperature. When they are exposed to high temperatures, they expand, and when they are cooled, they contract. However, this is seen in some materials more so than others, which nonetheless signifies distinct trials for component materials in demanding thermal applications.

The behavior of distinct materials, when subjected to different temperatures at consistent pressures, is known as the coefficient of thermal expansion (CTE). This value is expressed asnx 10-6/K and determines the severity of material size variations per degree in the change of temperature in a linear or volumetric plane.

Why are Thermal Expansion Coefficients Important?

With rising temperatures, the magnitude of thermal expansion usually increases concurrently. At moderately low thermal values, a proportional association between expansion and the rising temperature is expected to be seen by the CTE.

With higher thermal values, the thermodynamic properties of solid expansion become complicated. This is particularly seen in cases where components are physically constrained. In these instances, dimensional changes can cause materials to fail and fracture, resulting in the preferential need for low CTE materials in refractory applications with component housings or rigid equipment.

Extreme temperatures can skew CTE measurements, so the relationship between higher thermal values and volumetric change is disproportionate. This results in more complex mechanical instability and can result in harmful thermomechanical stress within the material’s mineral structure.

Technical Ceramics and Thermal Expansion Coefficients

与金属相比,技术陶瓷水资源teristically exhibit a lower CTE because of their unique structural makeup and low thermal conductivity. Metal alloys usually display thermal expansion coefficients between 10 - 30 x 10-6/k.

In comparison,Sialon陶瓷boast CTE as little as 3.0 x 10-6/k. This reflects ultra-low subjectivity to expansion at extreme temperatures. Additionally, the resistance to thermal expansion allows the material to display its usual physical integrity throughout continuous use. In contrast, traditional materials can start to show signs of not only thermal warping but also risks of fracture throughout extended service lives or continual hours of action.

Sialon Ceramics from International Syalons

For decades, International Syalons has concentrated on the enhancement of technical sialon ceramics. They have patented the material and are developing it for distinct application requirements.

They are dedicated to discovering new uses for the material and revealing the maximum thermal and mechanical capacities that are possible. Many of their sialon grades have been developed to deliver extraordinary thermal stability with a CTE of 3.0 x 10-6/k. This includes Syalon 101, Syalon 110, and Syalon 201. This entire family of ceramics is extremely formable and can be used in a vast range of applications.

This information has been sourced, reviewed and adapted from materials provided by International Syalons.

For more information on this source, please visit实习生ational Syalons.