对工程涂料的需求越来越严格。环境问题也被视为设计过程中不可或缺的一部分。因此,为了使未来的经济竞争力和较低的环境影响,我们必须将注意力转向使用最低资源的过程。热喷涂是一种有吸引力的涂料技术,因为它提供了各种材料和过程,与常规的镀层过程相比,对环境的影响减少了。欧洲杯足球竞彩 Thermal spray coating techniques such as flame spraying, wire arc spraying and plasma spraying, allow many problems of wear, corrosion and thermal degradation to be resolved by engineering the surface with tailor-made coatings. For example, turbines can be coated by thermally spraying, allowing their use at higher temperatures. 热喷涂如何工作?In the thermal spraying process, heated and melted particles are propelled towards a substrate where they are flattened and quenched very rapidly. A thermal sprayed coating consists of layers of splats which have a lamellar cross section. Typically the cooling rate of each splat is somewhere in the vicinity of one million degrees per second. This rapidly quenched microstructure can have unique characteristics quite unlike those produced by conventional processing techniques e.g. the extension of solid state solubility, refinement of grain size, formation of metastable phases and a high concentration of point defects. 热喷涂的变化热喷涂技术有很多变化。在火焰喷洒燃烧的火焰中,使用燃料来加热材料。在大气等离子体喷涂(AP)中,材料在等离子体射流中融化并加速。为了避免进料材料的氧化,可以在降低压力下(称为真空等离子体喷涂VPS或低压等离子体的LPP),在惰性气气中进行喷涂。在高速氧气燃料喷涂(HVOF)中,将材料注入到高速射流中,该射流是通过在高压下燃烧含氧的燃料而产生的。 Advantages of Thermal SprayingCompared to traditional surface modification processes, thermal spraying offers greater thickness capability, no part size restrictions, it can be performed in situ, and it produces minimal noxious waste. High processing temperatures allow deposition of many high melting point materials onto a relatively cold substrate. 应用和市场近年来,热喷涂的涂料已获得各种工业应用的广泛接纳 - 全球热喷涂涂料市场目前约为13.5亿美元。这种增长主要是技术领导的,高价值的等离子涂料占据了市场的份额。这些应用中的绝大多数都涉及耐磨性,尽管使用热喷涂涂层来打击高温腐蚀也继续受到相当大的工业和学术兴趣。使用这些喷涂的涂层以在严重的工作条件下实现可确定的生命周期。例如,已经广泛使用了热喷涂的涂层,以防止用于高强度的高强度低合金钢的应力腐蚀破裂,用于液体石油储气罐。热喷涂涂料可以提供的其他表面特性和功能是生物兼容性,电阻/电导率,热屏障和尺寸恢复。 Extensive use of thermal spray technology has been instrumental in Europe attaining worldwide leadership in the paper and textile industry. Pioneering applications of thermally sprayed wear resistant coatings to blades, rolls and looms have allowed a significant increase in production rates. The aeronautic and space industries have also benefited considerably - many components in modern aircraft depend on hard, wear resistant coatings which can withstand temperatures of about 850°C. This type of application represents approximately 40% of the total market. Surface ProtectionSurface protection at high temperatures has become one of the most advanced fields of modern engineering. Diverse examples include rocket thrust chamber linings, chemical reaction vessels, combustion vanes and land-based turbines for aircraft, and hot extrusion dies. These coatings usually consist of carefully selected ceramic and metal layers which provide adequate thermal fatigue resistance and corrosion protection. The use of protective coatings for corrosion prevention has grown rapidly during the past decade, and thermal spray coatings represent a significant portion of this growth. MicroelectronicsThermal sprayed coatings can also be used to manufacture hybrid microelectronic components, by spraying ceramic materials onto a metal substrate to provide electrically insulating areas. Such technology is becoming increasingly important in meeting the demands of modern computing. BiomaterialsBiomaterials account for about 41% of the total weight of thermal sprayed materials in the world. Biomedical requirements in prostheses are complex and diverse in nature. Often, a combination of coating materials is needed to suit the various stages of the bio-integration process of foreign material into the human body. Functionally graded bioceramic coatings are used to enhance both the biocompatability and corrosion resistance of implants. Mechanical Properties

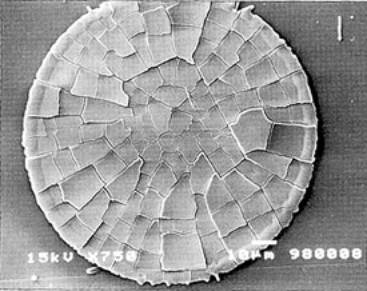

The mechanical properties of coatings depend strongly on their microstructure and especially on the porosity and the interlamellar contacts. These depend heavily on the consumables used and the processing route used. Hardness is one of the key properties of a thermally sprayed coating, as this is often used to give a first approximation of coating wear resistance. Measurements of hardness also allow a quick estimation of coating strength and the quality of spraying, because specific processing defects, such as porosity and unmelted grains, can lower coating hardness. Wear Resistant CoatingsCarbides and oxides are the hardest thermal sprayed coatings, the most commonly sprayed being WC-Co cermets. Cermet and ceramic coatings are therefore the most suitable for wear applications. The elastic moduli of the A13S sprayed coatings are significantly less than the bulk material. Carbides and oxides typically have a modulus which is 20-30% of the bulk value, though this value is heavily dependent on the processing route. Sprayed metal coatings generally have a modulus of about 30% of the bulk value, although this may be comparable with the bulk properties for coatings produced using the LLPS system. Thermal Barrier CoatingsThermal barrier coatings (TBCs) depend on low thermal conductivity and thermal diffusivity. The state-of-the-art TBC system at the moment is an air plasma sprayed Zr02/6-8wt% Y203在尼古拉粘结层层上的陶瓷层,通过在低压下喷洒血浆。部分稳定的氧化锆被选择为面漆,因为其极佳的热冲击性,低导热率和相对较高的热膨胀系数。由于喷涂,在单个隔板中产生的微裂纹网络进一步增强了热导率和应变耐受性。

|

Figure1.典型的等离子体喷涂的陶瓷Splat显示了微裂纹网络。 |

The FutureIn the future the manufacturing and engineering industries will continue to change dramatically, and for numerous engineering or consumer durable products appropriate surface engineering as applied by thermal spraying techniques is becoming a decisive factor in sustaining a competitive edge. 在可用的许多表面工程技术中,热喷雾技术尤其适合满足市场需求。它们允许制造各种涂料,精心制作的多材料(例如功能梯度涂层)的沉积,并为开发新的创新涂层提供了巨大的潜力,这些涂料可以通过最小的环境干扰来处理。欧洲杯足球竞彩 HVOFHVOF is expected to increase its share of the market significantly - hard cermet coatings are increasingly replacing conventional chrome plating, and oxidation resistant alloy coatings for turbine engines, which were sprayed exclusively by LPPS, are now also produced by HVOF. This is because the technique can produce very dense coatings with reduced oxidation and decomposition of the feed materials in air. 屏障涂料热喷雾技术最具挑战性的目标之一是耐腐蚀性的屏障式涂层,因为几乎完全清除了孔隙度。VPS在某种程度上已经成功,但是如果可以在空气中进行此类涂层,则可以实现更多的应用。为了实现这一目标,通过引入煤气罩或激光皮肤融化,对APS以及HVOF过程进行了改进。 Corrosion/Wear CoatingsCeramic coatings also merit greater consideration for applications involving corrosion plus wear. However, it is important that as much care is given to selection of the bond coat as to the ceramic coating if these coatings are to perform as well as anticipated. Conclusion改善陶瓷涂料的另一个可能的途径是利用新的结构陶瓷浪潮。诸如纤维载荷,受控和反应韧性等方法可以在涂料响应方面显着改善。 Thermal sprayed coatings may not be the answer to every problem involving surface degradation of a component, they are just one weapon in an arsenal. However, the technique does offer a great range of coating operations, and provides an appealing opportunity for innovation, while putting less pressure on environmental resources. |