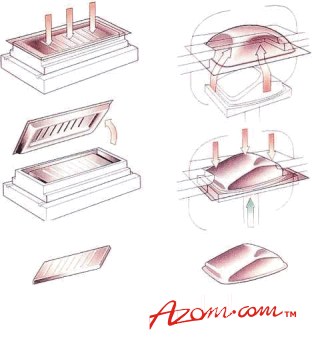

Superplastically formed (SPF) aluminium alloys have the ability to be stretched to several times their original size without failure when heated between 470-520°C. It is this superplasticity which allows components to be formed to a required shape by applying air pressure and/or tool movement within custom designed forming machines. 因此,该过程有效地将真空塑料的设计自由与所有材料优势和高性能合金的卓越机械完整性结合在一起。 超代形成的好处从设计和生产角度来看,该过程在仅二十年的时间里被商业开发了一系列重要的好处。首先,有能力在一个操作中形成具有双重曲率和平滑轮廓的组件,具有出色的尺寸精度和表面饰面,并且没有与冷形成技术相关的“弹回”。 Because only single surface tools are employed, lead times are short and prototyping is both rapid and easy, because a range of sheet alloy thicknesses can be tested on the same tool. By the same token, the (already modest) tooling costs are significantly lower than those employed by more conventional alternatives - typically costing around 10% of those used for matched die stamping, for example. 形成技术目前正在使用五种形成技术来利用这些优势。所选方法取决于设计和性能标准,例如大小,形状和合金特性。经常使用两种方法用于电信和电子行业。 腔形成第一个也是最常用的是形成腔,其中将预热的(SPF)铝板夹在位置,并通过气压被迫进入霉菌腔。该方法是从同一纸中生产多个组件的理想选择,从而降低单位成本(图1A)。 泡泡形成对于第二种技术,将气泡形成,将预热的合金夹在气泡板和工具板之间,并从下方引入气压以将纸张拉伸到气泡中,图1。the sheet’s original position and into the bubble until the sheet is evenly tensioned at the required height. Air pressure is then applied above the bubble, forcing the sheet into close contact with the tool, thus allowing the production of highly complex forms with increased aspect ratios and more uniform thickness distribution.

|

Figure 1.(a)形成腔和(b)SPF铝合金的气泡。 |

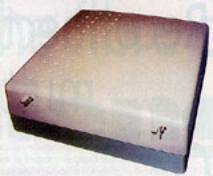

In both cases it should be noted that only one component surface comes into contact with the tool, thus enabling exceptional finish standards to be achieved. Other key benefits include the ability to reduce subassemblies, simultaneously eliminating joints. In fact, many new applications develop from design enhancements which not only reduce weight but also decrease or even obviate the need for fabrication, welding or cold forming as well as improving strength and repeatability. 更广泛的优势包括从模型,图纸或CAD数据中生产工具的灵活性,也用于加工以及合并特殊功能,以提高刚度和易于组装。最大形成尺寸约为2.7 x 1.5m,新鲜应用的范围非常宽,而合金本身可以通过粘合键合或焊接(如有必要)连接。他们还将接受各种表面处理,粉刷和粉末,符合国际标准。 申请in the Electronics Industry电子行业的潜力是显而易见的,因为这些属性中的许多实际上是标准的外壳要求。特别是对于电信制造商而言,该过程越来越具有挑战性的合成材料和常规金属形成,这些吸引人的自然强度RF和EMI屏蔽特性进一步提高了这些景点。 Nortel的Micro BTS户外外壳盖说明了如何利用这种设计和生产优势的组合(Micro BTS户外是一个环保的手机收发器基地,现在在法国,北美和香港部署,图2)。

|

Figure 2.用于手机基站的超塑形形成的铝制外壳的示例。 |

使用空腔形成方法的95 x 95厘米外部和内部盖的设计和生产规范分别从2.0mm的启动量表和1.6mm 5083(SPF)铝合金产生的外壳分别尤为要求。 除了实现审美标准以补充Nortel现有的产品组合外,这些封面还必须提供保护免受元素和极端温度的保护,以及在非常紧密的重量极限内的高水平破坏力。此外,他们还必须在短时间内符合EMC合规性和LTV稳定性的严格标准,并且与预期的产品量有关。 在仔细评估客户的替代方法之后,Explastic Aluminum成为最能满足所有标准的材料。探索的其他选项包括充满玻璃的聚合物造型和真空塑料,带有内部法拉第笼子和制造的铝制外壳。这些都无法满足所有标准。外部覆盖物是如此成功,以至于该过程也用于内部覆盖物。 |