Jeol USA,Inc。正在彻底改变3D印刷世界。在JEOL的特殊增材制造技术中,添加剂制造的创新正在以无与伦比的速度进行。

JEOL的电子束金属AM机器使能够清洁有效地生产在能源和航空航天部门中使用的较轻的制造零件。它通过高可重复性和高质量的建模,多个零件的组合以及减轻体重来增加产出和减少开发时间。

JEOL Additive Manufacturing Technology

JEOL has come up with a so-called “Electron Beam Metal AM Machine” that has a higher density, higher power, and higher speed compared to other laser beam techniques. This is done with the help of the technology of the world’s highest level performance electron microscope and electron beam lithography system for semiconductor manufacturing. It enables cost savings and design freedom via increased productivity.

Image Credit: JEOL USA, Inc

JAM-5200EBM

Long Life Cathode over 1,500 Hours and Helium-Free Electron Beam Metal AM Machine

Main Features

- Helium-Free and powder dispersal prevention system "e-Shield"

- Long Life Cathode

- 自动电子束校正

- Remote Monitoring System

- JEOL USA established, extensive service support organization

- 实现环保和可持续的社会

JEOL的增材制造优势

-

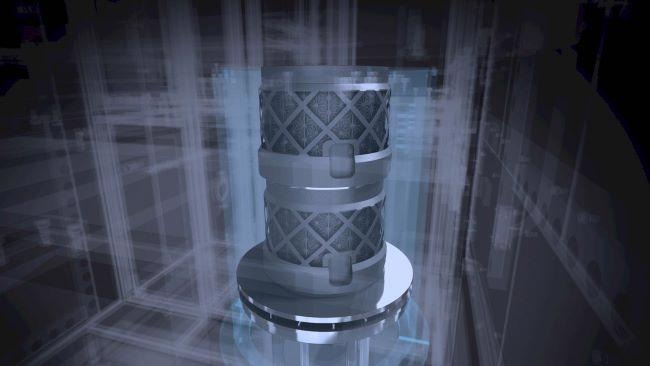

专注于总系统正常运行时间,以及超过1,500小时的长期阴极。完整的阴极寿命和制造质量保留在系统的清洁制造中。

-

干净无氦的环境和“电子屏幕”在制造时消除了烟雾事件。JEOL的特殊粉末分散预防系统可防止散射现象。

-

The potential to remotely track conditions and manufacturing status.

-

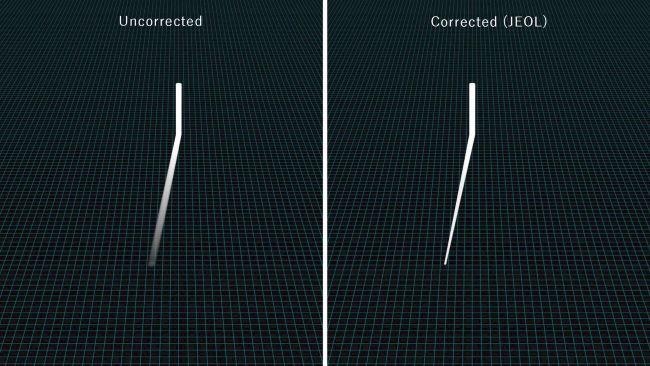

根据辐照位置,以自动方式校正电子束的焦点和斑点形状。该技术是基于公司在半导体制造的电子光束光刻系统中的市场领导地点开发的。

-

Manufacturing capacity is around 250 mm (diameter) × 400mm (height).

-

环保制造。该系统能够在一次运行中构建几个部分。

-

JEOL USA目前由180多名现场服务工程师组成的广泛广泛网络。

A3D Printer Built on JEOL Expertise and Support

The unique feature of the JEOL JAM-5200EBM that makes it stand out in this emerging field is that it is backed by JEOL’s decades-long expertise in the development and production of sophisticated electron optics technology that has been utilized for research and industrial applications.

JEOL是电子显微镜仪器的市场领导者。它已经有助于从材料表征和粒子分析到成像和化学分析的3D打印值流。欧洲杯足球竞彩

JAM-5200EBM的电子束技术还借鉴了JEOL在使用特殊真空技术的掩模写作和点梁光刻工具的开发和生产方面拥有50多年的经验。

Long Life Cathode

“The Long-Life Cathode, which sustains more than 1,500 hours, could considerably decrease downtime for cathode replacement.” The secret is that JEOL’s original vacuum technology has been developed in the manufacturing of electron beam-related equipment.

Image Credit: JEOL USA, Inc

Helium-Free and Powder Dispersal Prevention System “e-Shield”

不需要氦气来停止粉末的散射。JEOL的特殊粉末分散预防系统可防止散射现象。由于环境不含氦气,不仅可以以可承受的成本在干净的空间中制造,而且“阴极的表面也不太容易受到损坏,从而使电子束保持稳定。”

因此,可以维持制造质量,直到阴极一生结束。

Image Credit: JEOL USA, Inc

自动电子束校正

根据电子光束光刻系统在半导体制造中开发的技术,根据辐照位置自动校正电子束的焦点和斑点形状。

Image Credit: JEOL USA, Inc

Remote Monitoring System

可以始终从远程位置验证制造状态和机器条件。它还带有警报通知功能。

Image Credit: JEOL USA, Inc

实现环保和可持续的社会

在Jeol的“电子束金属AM机器”的帮助下,用户有可能在单个打印过程中建立一部分。几乎不需要切割,从而阻止材料被浪费。欧洲杯足球竞彩重复使用金属粉是另一种可能性。因此,耶尔(Jeol)正在致力于实现一个可持续和环保的社会。

Image Credit: JEOL USA, Inc

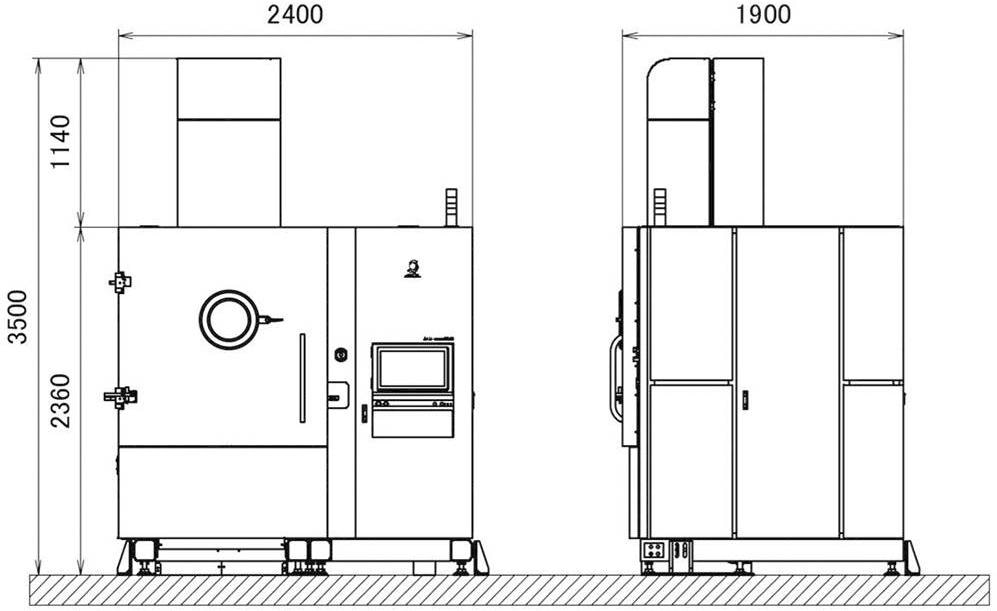

JAM-5200EBM

Technical Data

Dimensions. Image Credit: JEOL USA, Inc

Main Specifications. Source: JEOL USA, Inc

| 。 |

。 |

| Manufacturing method |

Powder bed fusion |

| 制造维度 |

最大250毫米(直径)×400毫米(h) |

| 电子束输出 |

最多6 kW |

| 阴极的寿命 |

1,500 h or longer |

| 腔室压力(熔化期间) |

0.01 Pa or lower |

| 惰性气(用于预防费用) |

Not required |

| Manufactured product cooling system |

配备了 |

| 粉末分散预防系统 |

电子屏幕 |

| Beam correction |

Automatic (Focus, Astigmatism, Distortion) |

| 电源 |

3相,200 V(±10%),35 kVa |

| Weight |

4,900公斤 |

| 数据格式 |

STL |

Jeol Electron Beam Metal AM Machine JAM-5200EBM

Jeol Electron Beam Metal AM Machine JAM-5200EBM。Video Credit: JEOL USA, Inc