2010年3月15日

A new high-performance anode structure based on silicon-carbon nanocomposite materials could significantly improve the performance of lithium-ion batteries used in a wide range of applications from hybrid vehicles to portable electronics.

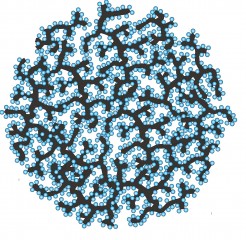

该示意图显示了通过分层自下而上组装过程形成的硅碳纳米复合颗粒。退火的碳黑颗粒被硅纳米颗粒覆盖,然后组装成具有欧洲杯猜球平台开放互连内部通道的刚性球体。

该示意图显示了通过分层自下而上组装过程形成的硅碳纳米复合颗粒。退火的碳黑颗粒被硅纳米颗粒覆盖,然后组装成具有欧洲杯猜球平台开放互连内部通道的刚性球体。

新结构以“自下而上”的自组装技术生产,利用纳米技术来微调其材料特性,以解决早期基于硅的电池阳极的缺点。欧洲杯足球竞彩简单的低成本制造技术旨在轻松扩展并与现有的电池制造兼容。

Details of the new self-assembly approach were published online in the journal Nature Materials on March 14.

"Development of a novel approach to producing hierarchical anode or cathode particles with controlled properties opens the door to many new directions for lithium-ion battery technology," said Gleb Yushin, an assistant professor in the School of Materials Science and Engineering at the佐治亚理工学院. "This is a significant step toward commercial production of silicon-based anode materials for lithium-ion batteries."

The popular and lightweight batteries work by transferring lithium ions between two electrodes - a cathode and an anode - through a liquid electrolyte. The more efficiently the lithium ions can enter the two electrodes during charge and discharge cycles, the larger the battery's capacity will be.

现有的锂离子电池依赖于用石墨制成的阳极,一种形式的碳。从理论上讲,基于硅的阳极比石墨的能力提高了十倍,但是基于硅的阳极到目前为止尚未足够稳定以进行实际使用。

Graphite anodes use particles ranging in size from 15 to 20 microns. If silicon particles of that size are simply substituted for the graphite, expansion and contraction as the lithium ions enter and leave the silicon creates cracks that quickly cause the anode to fail.

新的纳米复合材料解决了降解问题,可能允许电池设计人员利用硅的容量优势。这可能有助于从给定的电池尺寸的较高功率输出,或者允许较小的电池产生所需的电源。

Yushin说:“在纳米级,我们可以比在传统尺寸尺度上以更好的欧洲杯足球竞彩精度调整材料。”“这是一个纳米级制造技术导致更好材料的例子。”欧洲杯足球竞彩

Electrical measurements of the new composite anodes in small coin cells showed they had a capacity more than five times greater than the theoretical capacity of graphite.

Fabrication of the composite anode begins with formation of highly conductive branching structures - similar to the branches of a tree - made from carbon black nanoparticles annealed in a high-temperature tube furnace. Silicon nanospheres with diameters of less than 30 nanometers are then formed within the carbon structures using a chemical vapor deposition process. The silicon-carbon composite structures resemble "apples hanging on a tree."

Using graphitic carbon as an electrically-conductive binder, the silicon-carbon composites are then self-assembled into rigid spheres that have open, interconnected internal pore channels. The spheres, formed in sizes ranging from 10 to 30 microns, are used to form battery anodes. The relatively large composite powder size - a thousand times larger than individual silicon nanoparticles - allows easy powder processing for anode fabrication.

硅碳球中的内部通道有两个目的。他们承认液体电解质可以快速进入锂离子以快速电池充电,并提供空间以适应硅的扩张和收缩而不会破裂阳极。内部通道和纳米尺度颗粒还为阳极提供了短锂扩散路径,从而增强了电池功率特性。欧洲杯猜球平台

硅颗粒的大小由化学蒸气沉积过程的持续时间和施加到沉欧洲杯猜球平台积系统的压力控制。碳纳米结构分支的大小和硅球的大小决定了复合材料中的孔径。

Production of the silicon-carbon composites could be scaled up as a continuous process amenable to ultra high-volume powder manufacturing, Yushin said. Because the final composite spheres are relatively large when they are fabricated into anodes, the self-assembly technique avoids the potential health risks of handling nanoscale powders, he added.

一旦制造出来,纳米复合阳极就会像常规的石墨结构一样用于电池中。这将使电池制造商能够采用新的阳极材料,而无需对生产过程进行巨大变化。

到目前为止,研究人员已经通过一百多个电荷分离循环测试了新阳极。Yushin认为,对于数千个周期,由于没有降解机制,这种材料将保持稳定。

"If this technology can offer a lower cost on a capacity basis, or lighter weight compared to current techniques, this will help advance the market for lithium batteries," he said. "If we are able to produce less expensive batteries that last for a long time, this could also facilitate the adoption of many 'green' technologies, such as electric vehicles or solar cells."

除Yushin外,该论文的作者还包括Alexandre Magasinki,Patrick Dixon和Benjamin Hertzberg(来自佐治亚理工学院),以及威斯康星大学麦迪逊分校的材料科学中心和材料科学系的Alexander Kvit,以及来自Superiorphaphite的Jorge Ayala。欧洲杯足球竞彩欧洲杯线上买球该论文还感谢克莱姆森大学的佐治亚理工学院和伊戈尔·卢齐诺夫的贡献。