在全球范围内,对高质量太阳能电池的需求正在增加。这对细胞生产者施加了压力,要求对细胞可靠,完全自动排序。基于摄像机的质量检查和细胞CLAS尺寸可以集成到现有的细胞测试仪/分类器中。在SNEC 2013 Vitronic在中国光伏行业的礼物中,其Vinspecsolar VCOFLC1相机系统可以实现精确可靠的前印刷和颜色检查,比人的眼睛更能做到。

Camera-based quality inspection system

Camera-based quality inspection system

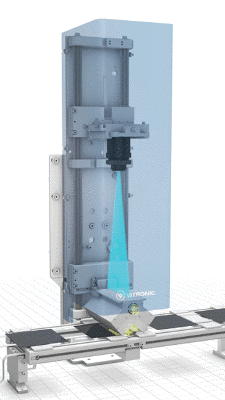

Tier One customers require high quality solar cells. Especially sorting into different color classes is a main scope at Asian factories. Therefore many Asian solar cell producers consider how to retrofitting their existing production plants. The new VINSPECsolar VCOFLC1 camera system combines front print and color inspection, and performs exact and reliable quality inspection and cell classification. VINSPECsolar VCOFLC1 enables easy operation, calibration and reliable and robust performance at competitive pricing. VITRONIC provides a standard calibration tool to define the color classes and borderlines. Even if several cell testers have to be operated and tool matching is required: the set up process needs to be done only once and the classification rules can be copied to all other testers.

技术说明

The inspection system can be used for both mono and multicrystalline silicon cells. Its throughput achieves more than 2,400/h, and the sorting pureness is higher than 99.8 percent. The sensor box consists of a color line scan camera with four 4,096 (4k) pixels lines, a white LED illumination module, a backlight and a computing subsystem. The software – developed by VITRONIC - provides automated, fast tool calibration and tool matching, a graphical user interface comprising yield control tools for rapid intervention and process adjustments, statistics and visualization of all quality relevant features of current and recently tested cells.