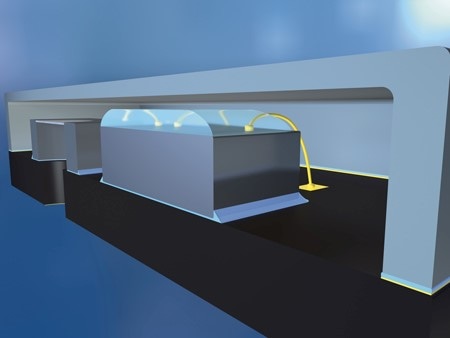

DELO has developed new glob top adhesives featuring optimized flow properties. They allow chips, for example in MEMS sensors, to be coated in a uniform thickness of less than 100 µm that does not extend beyond the chip edges.

New die coating materials make it possible to achieve layer thicknesses of <100 µm.

New die coating materials make it possible to achieve layer thicknesses of <100 µm.

Increasing miniaturization in microelectronic packaging gives rise to new demands on the glob top materials used. For example, manufacturers of mobile phones are now demanding a maximum thickness of 0.6 mm for MEMS packages. That means that the die coating materials used to protect the chip upper side have to be as flat as possible. The use of DELO heat-curing acrylates yields convincing results, especially when a uniform and reliable coating that does not flow beyond the chip edges is to be applied to the upper side of chips.

不仅仅是粘合剂

Adhesives developed by DELO have a low viscosity and special flow properties. They can thus be processed efficiently by jetting and, compared to conventional die coating materials, make it possible to achieve a homogenous flat surface with a layer thickness of less than 100 µm using just a few drops. A further benefit is the high flexibility (shore hardness A60) reducing the risk of stresses in the chip and the wires.

除了小涂层厚度外,还有另一个积极的方面。黑色粘合剂不仅可以保护和保留芯片表面,还可以覆盖其逻辑结构。这种特殊的黑色粘合剂还可以完美覆盖层特别薄的芯片角。另一个优点是,优化的流属性允许涂层各种芯片尺寸。