即使在最先进的机器上,在拉伸吹塑过程中,PET瓶材料的分布也可能存在差异。这对瓶子质量和生产效率有影响。

((Source: KHS Group)

((Source: KHS Group)

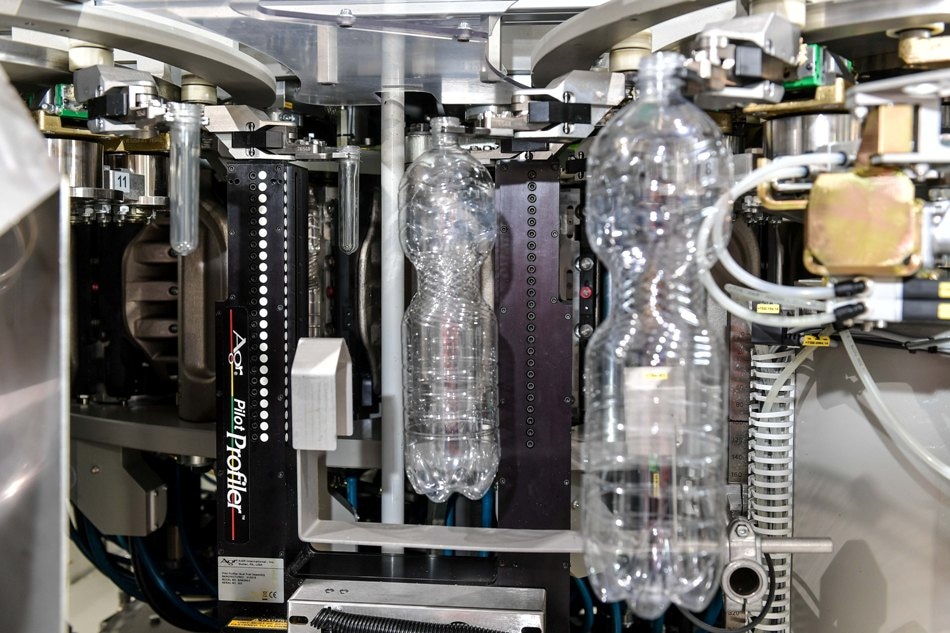

为了优化这些参数,KHS最近与美国公司AGR International Inc.合作开发了单元模具控制。(农业)。这个与KHS控制器相连的数字自动化过程控制系统现在单独调节KHS Innopet Blomax系列中的各自的吹风站,从而最大程度地减少了拉伸吹塑过程中质量的任何波动。这导致改善的瓶子稳定性以及较低的预成型重量。这证明了迄今为止的挑战,尤其是在使用高回收宠物含量的容器的情况下。

在拉伸吹塑器上,所使用的单个吹动阀上的磨损量可能会有所不同。这意味着,在拉伸吹塑器的整个使用寿命中,吹散的瓶子也会根据所使用的车站而发生变化。在生产过程中,这可能会导致材料分布的差异,从而导致瓶壁的厚度不同。迄今为止,只能针对整个机器而不是每个站点调整参数。使用新的数字单元模具控制系统制造商通过为每个站进行单个设置来优化其吹塑过程。“This enables material distribution to be more precisely controlled per station, thus minimizing variations in the wall thickness from mold to mold by more than 30%,”explains Frank Haesendonckx, head of Technology at KHS Corpoplast.

单元模具控制可自动调整设置

为此,单位模具控制检查技术不断测量每个瓶子中的材料分布,并调整设置以完全自动优化。“With this system deviations in the individual mold stations are identified. By applying an algorithm the degree of variability is reduced without operator intervention and possible incorrect settings are avoided,”州Haesendonckx。此外,例如,从单个霉菌站捕获的数据为阀门,拉伸系统或模具外壳的基于条件的维护提供了宝贵的信息。

单位霉菌控制尤其是在PET瓶中使用的回收物的增长,从而产生了进一步的好处。“过程准确性达到了诸如此类的容器的限制,”Haesendonckx says.“As the material quality varies when recycled PET is used, the bottle becomes less and less stable the less the preform weighs or manufacturers have to use heavier preforms to ensure stability.”With the new system weights can be reduced while retaining bottle stability, claims Haesendonckx.“Unit Mold Control effectively compensates for discrepancies by identifying any unwanted material displacement during wall thickness inspection and automatically counteracting this.”

Partner Agr is also convinced by the joint new development.“Our commitment to the global beverage market is to provide innovative process control solutions for the factory floor,”says Robert Cowden, COO of AGR.“这样做,我们正在帮助不断优化流程,并通过减少计划外的停机时间,每个生产容器和能源成本的劳动内容来提高生产线效率和生产率。”

Unit Mold Control is available as an option for KHS InnoPET Blomax Series IV and V stretch blow molders and has already successfully proved itself on the market several times over. Furthermore, the new system – whose industrial property rights are held by KHS and Agr – can also be retrofitted into existing plant machinery.

Source:https://www.khs.com/en/