Researchers from China recently fabricated super-elastic graphene aerogels (SGA) using ambient pressure drying, thus enabling the large-scale preparation of high-performance graphene aerogels. The as-prepared SGA showed better overall performance and remarkable oil adsorption compared to graphene aerogels produced by freeze-drying.

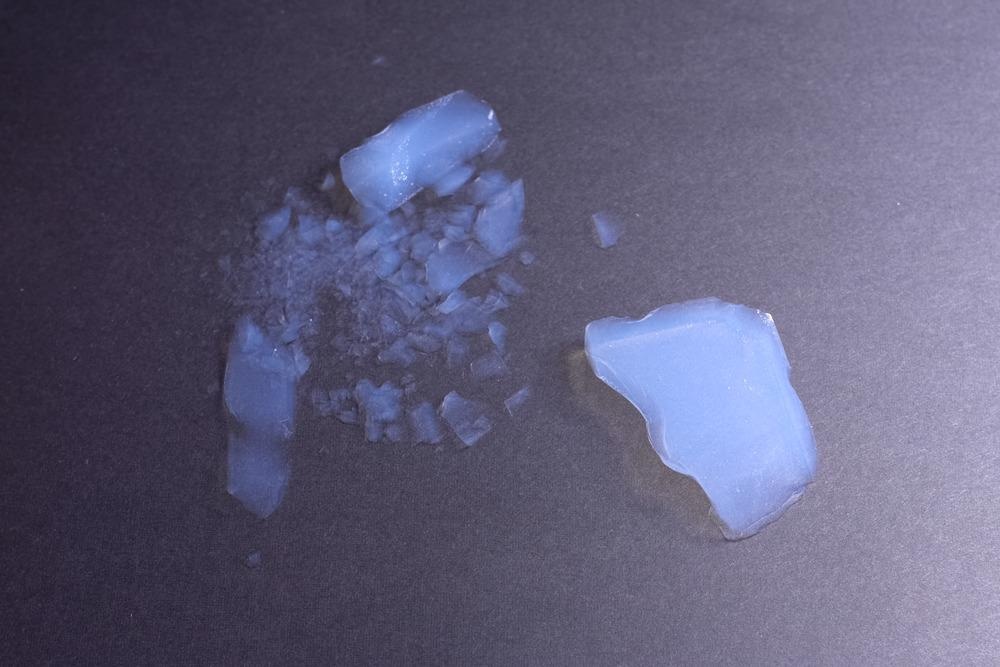

学习:Fabrication of super-elastic graphene aerogels by ambient pressure drying and application to adsorption of oils. Image Credit: LuYago/Shutterstock.com

该研究发表在中国化学工程杂志.

Challenges in Preparing Graphene Aerogels

三维(3D)基于石墨烯的气凝胶是由二维石墨烯片组成的高度多孔碳材料。欧洲杯足球竞彩由于其高比表面积和超低密度,它们被广泛用于油的吸附和环境恢复应用中。然而,机械性能差,高制造成本以及基于石墨烯基凝胶的回收效率低,阻碍了进一步的研究。

Atmospheric pressure drying is a technique used to fabricate graphene aerogels and is performed under ambient pressure. Compared to freeze-drying and supercritical drying, its advantages include ease of use, low energy consumption, and short production cycles. However, the graphene aerogel is usually not strong enough to withstand the capillary pressure generated during solvent evaporation under ambient pressure and temperature conditions. This causes volume shrinkage and collapse of the graphene aerogel structure. Thus, atmospheric drying is a major challenge in the industrial fabrication of high-performance graphene aerogel.

In this work, researchers prepared SGA via a process involving one-step freezing, twice hydrothermal reduction, and drying under ambient pressure. The as-prepared SGA can resist solvent evaporation and showed no volume shrinkage during ambient pressure drying.

What did the Researchers Do?

Graphene hydrogel was produced by the reduction of graphene oxide (GO) followed by freezing the prepared hydrogel under -30 °C for 1 h and thawing again at 90 °C for 200 min. The hydrogel was then washed with ethanol and dried to obtain graphene aerogel.

Increasing Performance of 3D Printed MXene Aerogels

The GO and SGA functional group structures were analyzed using Fourier transform infrared spectroscopy (FTIR) and their crystal structures were studied with the help of an X-ray diffractometer (XRD). A scanning electron microscope (SEM) was used to observe the microstructures of SGA. The researchers also analyzed the morphology, surface properties, and adsorption properties of the SGA.

What Did They Find?

The researchers analyzed the effect of reducing agent dosage, pH value, and pre-reduction time on aerogel formation. They found that the degree of contraction of aerogels became more significant with the increase of reducing agents (L ascorbic acid). This is because as the amount of reducing agent increased, deoxidation increased, which in turn increased the π-π interaction between the graphene sheets and thus, the volume of the formed graphene aerogel decreased.

他们还发现,捕获时间可以直接影响石墨烯气凝胶体积,并且通过逐渐增加捕获时间来获得完美的3D石墨烯气凝胶。但是,当还原前的时间超过一定值时,π-π力变得如此大,导致石墨烯片之间的严重堆叠,从而导致气凝胶体积的巨大收缩。

Regarding pH, the color of GO dispersion was found to gradually deepen with the increase in pH. Also, the volume and porosity of the aerogel prepared under acidic conditions were significantly greater than that prepared under alkaline conditions.

SGA的优势

The simple atmospheric drying process used in this work facilitates the large-scale preparation of high-performance graphene aerogels. The as-prepared SGA had a highly repeatable compression rebound and also exhibited remarkable oil adsorption performance.

The freezing process facilitates the formation of a 3D porous aerogel structure by forming ice crystals, that increase the pore wall folding, which leads to improvement in the mechanical properties of the aerogel. Thus, freezing enhances the skeletal strength of the aerogel to withstand the capillary pressure during drying.

与使用冻干方法制备的大多数石墨烯气管相比,准备好的SGA表现出更好的总体性能。SGA有能力以70%的应变300次返回其原始形状和高度。

在测试SGA对环己烷的吸附剂的SGA的环状吸附能力时,发现经过50倍的环状吸附吸附能力,SGA的环己烷的吸附能力仍然约为原始值的90%,这比最近报道的所有最近报道的石墨烯烯基凝胶都要大。

Conclusions

To summarize, the work demonstrated the preparation of a highly compressible, super-elastic SGA from GO and L-ascorbic acid using a process involving one-step freezing and two-step hydrothermal reduction under ambient pressure.

这些石墨烯气管的出色压缩弹性和疲劳强度意味着即使300个压缩循环也不会损坏SGA表面和结构。SGA的吸附能力为92.94厘米3g and an excellent cyclic adsorption ability for organic compounds. Thanks to its improved properties, SGA prepared using the atmospheric drying process can have extensive applications in oil adsorption.

来源

X. Zhao, W. Xu, S. Chen, H. Liu, X. Yan, Y. Bao, Z. Liu, F. Yang, H. Zhang, P. Yu, Fabrication of super-elastic graphene aerogels by ambient pressure drying and application to adsorption of oils,中国化学工程杂志(2021), doi:https://www.sciencedirect.com/science/article/pii/S1004954121005711?via%3Dihub

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of theTerms and conditionsof use of this website.