A study recently published in the journalCleaner Materialsevaluates the impacts of recycling waste PET as a partial substitute for fine natural aggregates on the workability, mechanical, microstructural, economic, and thermal properties of concrete.

Study:Evaluation of eco-friendly concrete having waste PET as fine aggregates. Image Credit: iamshutter/Shutterstock.com

Plastic waste constitutes to have a negative impact on the world’s oceans and natural environment. Globally, there is around 8.3 billion tons of plastic have accumulated since 1950, with 6.3 billion tons of that turned into waste. Of this waste plastic, current trends show that about 9% is being completely recycled each year, with 79% ending up as landfill and the remaining 12% incinerated.

PET is completely recyclable yet only 30% of all polyethylene terephthalate (PET) is currently being recycled. This is the plastic most commonly used for the manufacture of plastic water bottles and food packaging.

Researchers have shown how heat-processed PET-modified concrete is suitable for structural applications as it exhibits fresh, mechanical, microstructural, and thermal properties:“Other benefits include improved thermal insulation, reduced initial construction costs, and reduced manufacturing and handling times,”states study lead author Gideon O. Bamigboye of the Department of Civil Engineering, Covenant University, Ota, Nigeria.

Two Birds, One Stone

What makes the possibility of recycling PET for use as an aggregate in concrete an attractive prospect is that after water, concrete is the second most utilized substance on the planet. The material is the cornerstone of modern development as it is used in the construction of homes putting a roof over the head of billions of people, facilitating infrastructure for healthcare, education, transport, energy, and industry as well as fortifying our defenses against natural disaster.

However, the extensive use of concrete also comes at a great cost as the cement industry produces around 2.8 billion tons of CO2annually, equivalent to 8% of the global total – if the cement industry were a country, it would be the third-largest emitter of CO2after the US and China.

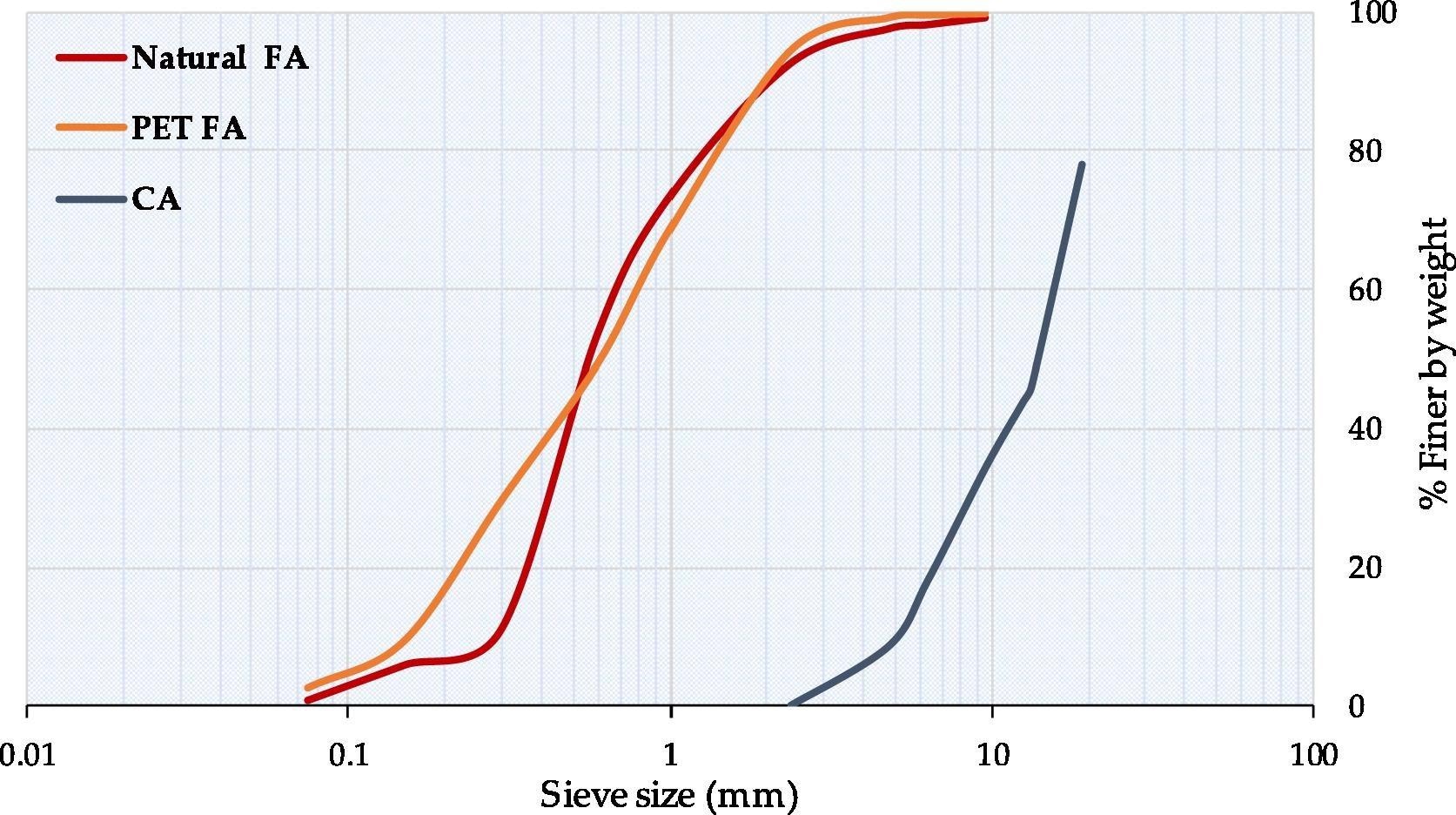

Particle size distribution curves for aggregates. Image Credit: Gideon O et al., Cleaner Materials

Furthermore, with cement use set to rise as global urbanization and infrastructure expands, finding solutions to reduce its carbon footprint is extremely urgent, now more than ever. Combined with the plastic problem, suddenly, recycling waste plastic bottles for use as a partial substitute for fine natural aggregates in concrete production looks like a “two birds, one stone” solution.

The production of concrete is also heavily reliant on natural resources for mineral aggregates and damages the most fertile layer of the earth, the topsoil. Aggregates are the most mined materials in the world and many mining sites also have the potential to be agricultural sites.

PET

In their study, the researchers comparatively evaluated the use of fine and coarse natural aggregates with plastic aggregates produced from recycled PET bottles. In order to produce the plastic aggregates the team subjected the PET water bottles to various heating and cooling processes before mechanically grinding up the material to produce a suitable fine aggregate.

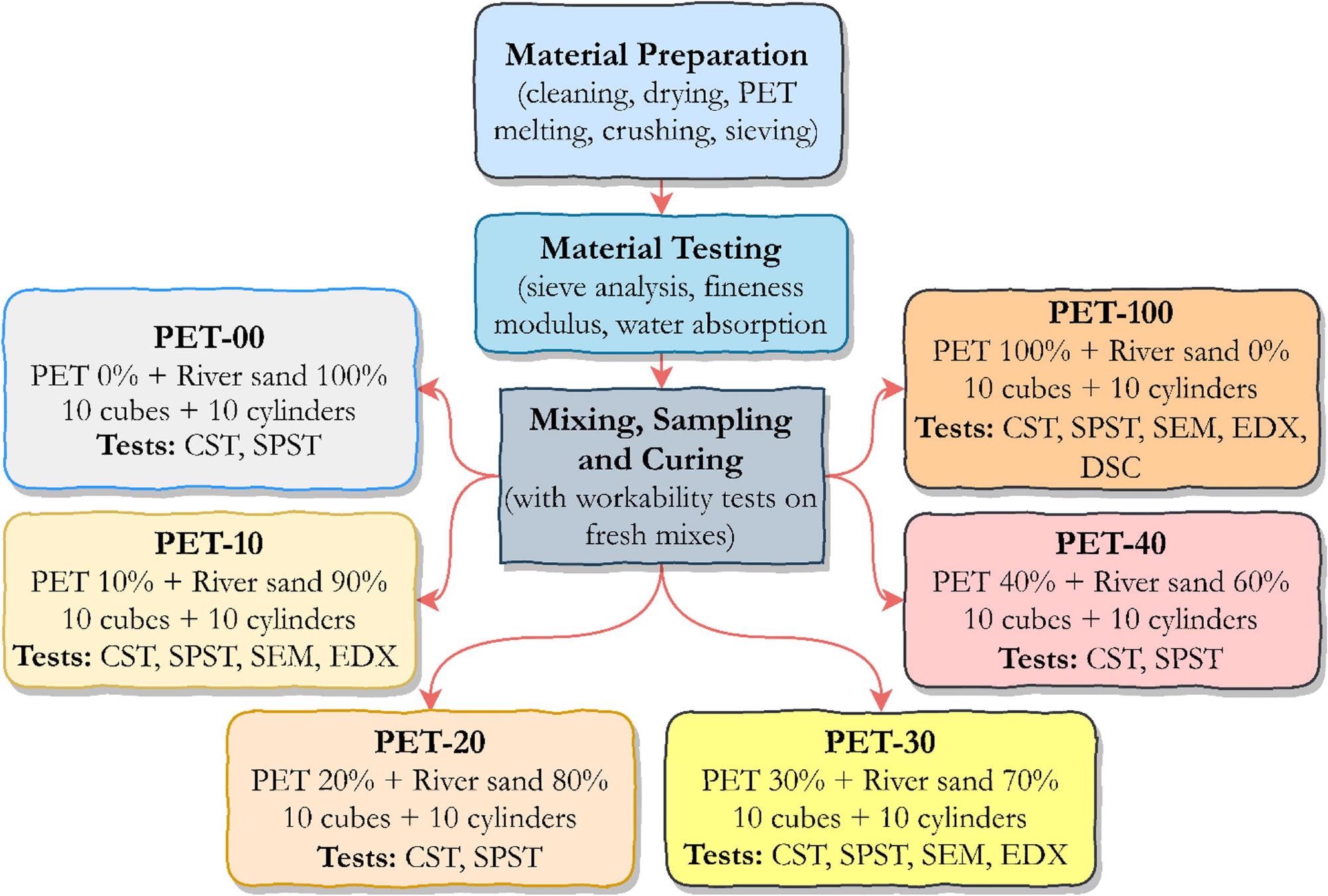

The team then set about creating a number of aggregate mixtures with varying percentage ratios of natural sand and PET (100:0, 90:10, 80:20, 70:30, 60:40, and 0:100). These batches were then subjected to various tests such as workability, tensile strength, and microstructural and thermal analysis.

Among their findings, the team discovered that increasing the percentages of PET plastics increased the workability of the concrete. However, this was only true up to the 40% value of PET inclusion, when PET levels exceeded this in the mix then there was a decline in workability:“Nonetheless, all PET batches attained workability values suitable for low to nominal reinforcement works,”explains Bamigboye.

Experimental program. Image Credit: Gideon O et al., Cleaner Materials

Furthermore, the team also revealed that the cost of PET is seemingly more economical and cost-effective for the slump testing approach, yet fine natural aggregates generate better economic outcomes in relation to the compressive strength.

Additionally, PET additions also demonstrated a negative decrease in both tensile and compressive strength tests. Therefore, further work is needed to find ways to improve these properties when using PET as a substitute fine aggregate in concrete.

However, all-in-all, the researchers were able to demonstrate that heat-processed PET-modified concrete is appropriate for structural applications and is environmentally friendly and sustainable as it conserves natural resources which make for promising news.

Many would agree that finding ways to expand global infrastructure and protect humanity against natural disasters should not come at the cost of the planet itself, ensuring minimal environmental impact when producing and using concrete and helping mitigate the plastic pollution problem go some way to achieving eco-friendly goals.

References and Further Reading

Gideon O. Bamigboye, Karnik Tarverdi, Amarachi Umoren, Daniel E. Bassey, Uchechukwu Okorie, Joel Adediran, ‘Evaluation of eco-friendly concrete having waste PET as fine aggregates’.Cleaner Materials, Volume 2, 2021, DOI:https://www.sciencedirect.com/science/article/pii/S2772397621000265?via%3Dihub

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of theTerms and conditionsof use of this website.