利用添加剂制造过程打印功能性集成热电设备具有巨大的材料科学领域潜力。欧洲杯足球竞彩欧洲杯线上买球发表在ACS能量信探索了这个主题,介绍了添加剂制造的热电材料和设备的开发的最新摘要和前景。欧洲杯足球竞彩

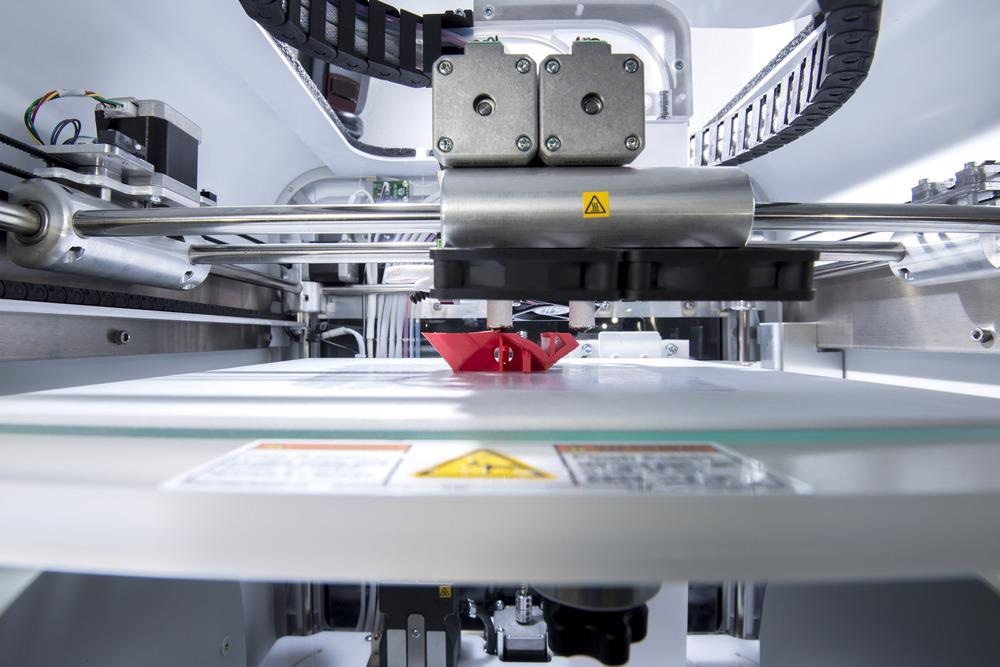

学习:热电学增材制造:新兴趋势和前景。Image Credit: RomboStudio/Shutterstock.com

Thermoelectrics

The field of thermoelectrics is a mature one. Since the discovery of thermoelectric materials two hundred years ago, research has progressed significantly. Recent studies have reported superior thermoelectric performance and techniques for fabricating both traditional and novel materials have become well-established.

Recent advances in the field currently have particular relevance due to the development of low-power technologies such as Internet of Things (IoT) and wearable devices. Moreover, the urgent need to rapidly decarbonize industry and reach net-zero emissions has facilitated interest in alternative energy sources for new generations of devices.

利用热电材料用于无电池传感器,自动化技术和芯片冷却的兴趣越来越大。欧洲杯足球竞彩热电学可以作为热电发生器和热电冷却器发挥双重作用。这些材料在系统级别上的性能取决于设备质量和材料性能欧洲杯足球竞彩等因素。在材料水平欧洲杯足球竞彩上,性能受工作温度,电导率和导热率以及Seebeck系数等特性的控制。

Due to the challenges in constructing thermoelectric devices, device design and manufacturing methods have not been studied as much as materials properties in recent years. Fabrication methods such as zone melting and hot pressing are used for thermoelectric materials, which are complex and energy-consuming. Materials tend to be bulky and rigid. Devices are limited in terms of geometrical complexity and practical application. Moreover, in contrast to other semiconductor technologies, research into scaling thermoelectric devices is less mature.

目前,将热电组件实施到可穿戴设备中以利用潜在的体热是流行的研究方向。已经开展了将灵活性引入热电设备的工作,其中一些研究使用液体 - 金属嵌入式弹性体等材料进行了研究。欧洲杯足球竞彩其他研究已经探索了热电材料沉积到柔性底物上。

3D打印热电设备

Additive manufacturing, otherwise known as 3D printing, is one of the pillars of Industry 5.0. This technological field has advantages in overcoming the challenges of thermoelectric device design and scalability. For instance, promising progress in using 3D printing to fabricate thermoelectric generators with versatile shapes has been made in recent years.

有许多不同的添加剂制造方法可商购。其中包括增值税光聚合,粉末床融合方法,材料喷射技术以及基于挤出的方法(例如直接墨水写作)。欧洲杯足球竞彩每个都有其自己的特殊优点和缺点,并且某些方法不适合3D打印热电材料。欧洲杯足球竞彩

在当前开发的各种3D打印技术中,直接墨水写作(DIW)表现出了针对具有复杂架构和增强灵活性的功能热电设备的特殊希望。该方法通过挤出喷嘴沉积墨水(也称为“浆液”)。

挤出打印方法(例如DIW)具有多个优点。可用于挤出印刷的大量墨水和材料有助于制造完全印刷的多物质欧洲杯足球竞彩热电设备的可能性。直接墨水写作在成本效益,减少材料废物和降低能耗方面也具有优势。欧洲杯足球竞彩

Given the recent emergence of 3D printed thermoelectric materials (within the past decade) the zT value of these materials is not as competitive as their conventionally fabricated counterparts. The zT value quantifies the material’s thermoelectric performance. However, due to the advantages of additive manufacturing over conventional fabrication methods and the potential for further optimization, direct ink writing is a promising process for the manufacture of high-performance thermoelectric devices.

The Study

焦点评论发表在ACS能量信提供对该领域的见解。已经探索了用于制造高性能热电材料和设备的配方和设备策略。欧洲杯足球竞彩作者指出,通过利用3D添加剂制造的印刷配方和功能来改善设备和材料功能的角度,缺乏文献。

The study starts with a summary of various 3D printing technologies and evaluates them as suitable techniques for thermoelectric material and device fabrication. Research elaborating on direct ink writing and its use for this purpose are explored, with a specific focus on DIW methodologies for fabricating inorganic thermoelectric inks due to their higher zT values than organic inks.

最后,重点审查调查了3D打印的热电材料与其常规制作的同行之间的性能差距,以解决问题,并为该领域的未来研究方向提供了一个观点,这将克服这些性能差距。欧洲杯足球竞彩

Further Reading

张,D等。(2022)热电学增材制造:新兴趋势和前景[online]ACS Energy Lett.2022 (7) pp. 720-735 | pubs.acs.org. Available at:https://pubs.acs.org/doi/10.1021/acsenergylett.1C02553

免责声明:此处表达的观点是以其私人身份表达的作者的观点,不一定代表AZOM.com的观点有限的T/A Azonetwork本网站的所有者和运营商。此免责声明构成了条款和条件使用此网站。