经过Susha Cheriyedath, M.Sc.Feb 21 2022Reviewed bySkyla Baily

经过Susha Cheriyedath, M.Sc.Feb 21 2022Reviewed bySkyla Baily

In a study published in the journal欧洲杯足球竞彩,,,,researchers evaluated the impact of microporosity on osteoconductivity and the osteoclastic resorbability of hydroxyapatite (HA)-based scaffolds for bone regeneration.

Study:3D-Printed HA-Based Scaffolds for Bone Regeneration: Microporosity, Osteoconduction and Osteoclastic Resorption.Image Credit: Sirisak_baokaew/Shutterstock.com

背景

The need for user-friendly and convenient bone grafts has led to the emergence of bone tissue engineering, which aims at regenerating bone and bringing back its lost function in the body. The use of bone substitutes and scaffolds has been found to be advantageous for bone regeneration.

A method of building objects layer by layer called additive manufacturing is used for building bone substitutes. Three-dimensional (3D) printing with three levels of architecture can be used for manufacturing these substitutes. The micro- and macro-architecture of bone substitutes can be realized through additive manufacturing.

骨骼缺陷决定了宏观结构,而植入物是患者特异性的,并且与骨缺损的类型不同。微体系结构由3D打印材料的预定分布定义。3D打印支架的纳米结构受后处理技术(例如较小规模的烧结温度)的影响。然而,脚手架微体系结构和纳米结构在整骨传导中的相关性尚不清楚。

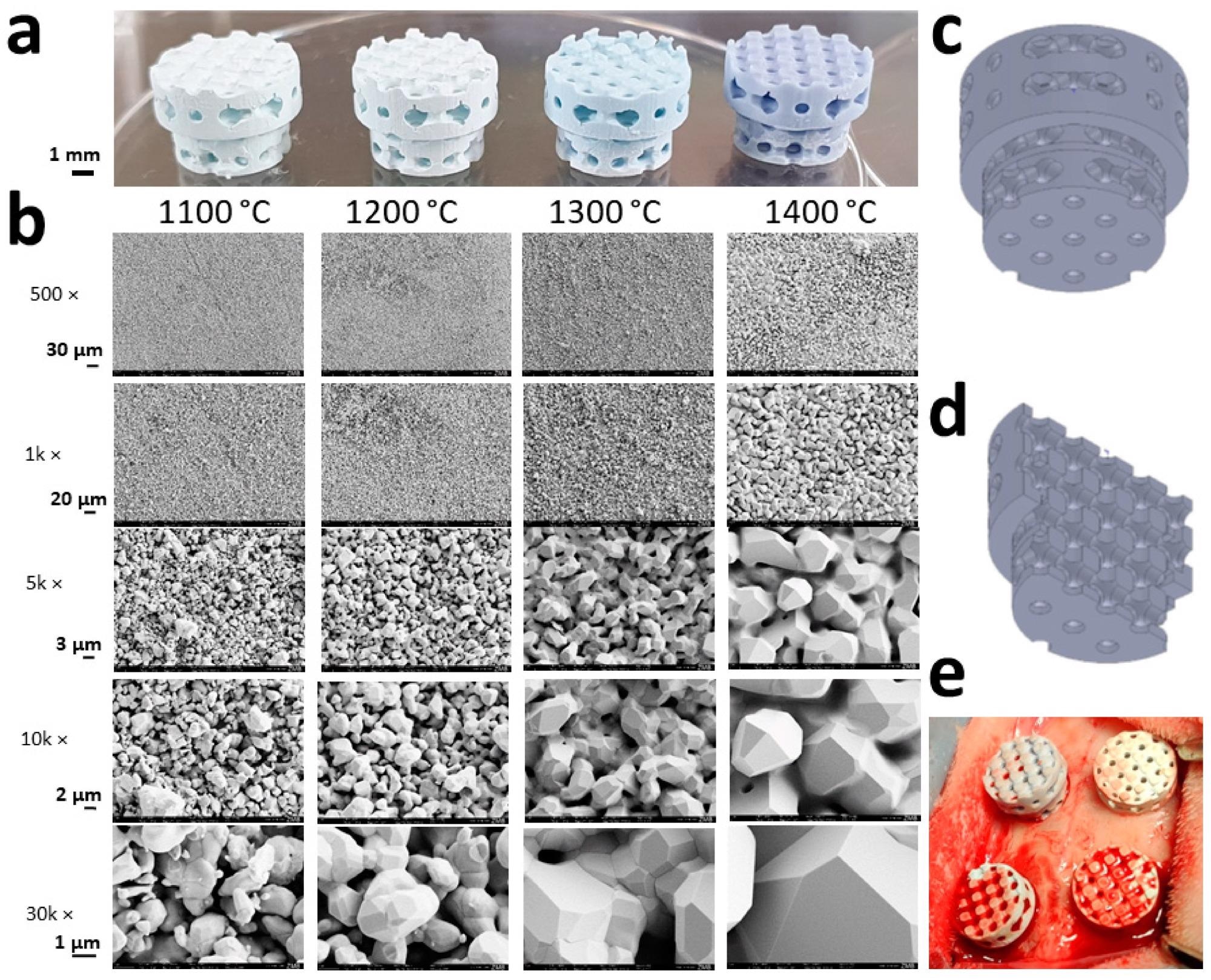

实验脚手架的摩托图和SEM图像:(一种)经历了不同烧结温度的脚手架被证明可以保持其宏观和微体系结构。(b)sintering temperatures applying to panel a and b are provided. SEM micrographs from the respective scaffolds are displayed with scales to the left;(C)the macroarchitecture of the full scaffold;(d)the macroarchitecture of the halved scaffold;((e)提供了将所有四个不同脚手架放置在兔子缺损中的所有四个脚手架后拍摄的图片。图片来源:Ghayor,C等,材料欧洲杯足球竞彩

先前关于磷酸三碳(TCP)基于基于三卡氏菌的脚手架的研究表明,在高微孔方面的破骨率增强。由于骨头主要由HA晶体制成,因此本研究的研究人员检查了HA支架用于骨再生的使用。研究小组还分析了骨骼替代物的特性,例如破骨,微孔和骨质碎裂的吸收。

关于研究

该团队使用具有相等的宏观和微体系结构但不同的纳米结构的HA创建了基于光刻的骨导型支架。这是通过将最大烧结温度从1100°C增加到1400°C来实现的。还测量了各种支架类型的微孔度,压缩强度和刚度。在钙化缺陷模型中,在10个成年新西兰白兔子的体内测试了支架的破骨传导性。

A scanning electron microscope (SEM) was used to analyze the scaffolds, while the microporosity was experimentally measured from the quantity of distilled water absorbed by the test scaffolds. A software program called TestXpert V11.02 was used to measure the maximal compression strength, while bony bridging was determined as a measure of osteoconduction.

![Comparison of osteoconductivity in relation to microporosity and compression strength between otherwise identical HA- and TCP-based scaffolds. The results for TCP-based scaffolds produced with the identical stl-file were generated and reported earlier [10]. (a) Osteoconductivity related to microporosity of test samples; (b) osteoconductivity related to compression strength of the partially sintered scaffolds. The values are displayed as mean ± standard deviation. The range for cancellous bone (2–12 N/mm2) depicted in the green shaded area was taken from [34].](https://d12oja0ew7x0i8.cloudfront.net/images/news/ImageForNews_58284_1645438235038609.jpg)

Comparison of osteoconductivity in relation to microporosity and compression strength between otherwise identical HA- and TCP-based scaffolds. The results for TCP-based scaffolds produced with the identical stl-file were generated.(一种)Osteoconductivity related to microporosity of test samples;(b)与部分烧结的支架的压缩强度有关的破骨电导率。值显示为平均值±标准偏差。图片来源:Ghayor,C等,材料欧洲杯足球竞彩

观察

分析了基于HA的支架,以检查微孔度是否影响骨骼,破骨和骨质碎屑吸收的形成。团队推断,使用无法区分和开放的可渗透微体系结构的脚手架的颅骨畸形的破坏和恢复是所有平台类型的主导地位。

Also, no critical contrast between top sintering temperatures from 1100 to 1400 °C and microporosities in the range of 0 and 46% has been distinguished. The HA scaffolds showed higher osteoconductivity compared to TCP-based ones, and on the periphery of these HA scaffolds, the formation and disintegration of osteoclasts were observed.

HA grains grew based on the sintering temperature from 1.07 ± 0.46 µm at 1100 °C to 5.98 ± 1.11 µm at 1400 °C and also underwent partial fusion. The diameter of the micropore expanded from 1.17 ± 0.47 µm at 1100 °C to 1.67 ± 0.52 µm at 1400 °C. In addition, surface and microporosity were impacted by partial sintering. While the surface reduced from 0.79 m2/g在1100°C至0.24 m2/g在1400°C,微孔度从45.85±0.39%降至0.74±1.87%。

经过adjusting the sintering temperature, the researchers were able to control grain size, micropore diameter, and overall microporosity. Microporosity was analyzed from the weight gain caused due to infiltration with distilled water. HA-based scaffolds were adequate to improve the in vivo bone formation since they exhibited an increase in microporosity from 10 to 20% for a porosity of 80%.

High osteoconductivity was observed with sintering temperatures between 1100 and 1300 °C and microporosities at 18 and 46%. Since osteoconductivity decreased at 1400 °C, phase transformation had a minor impact on osteoconductivity or osteoclastic degradability.

与TCP相比,HA支架的生产具有高度的机械强度和骨电导性,因此比TCP更好。CA2+dissolution curves of the HA-based scaffolds appeared parallel and were similar for all sintering temperatures. The team concentrated on HA-based scaffolds with grain sizes in the range of 1.07 and 5.98 µm and witnessed osteoclast arrangement and movement on every surface and grain size.

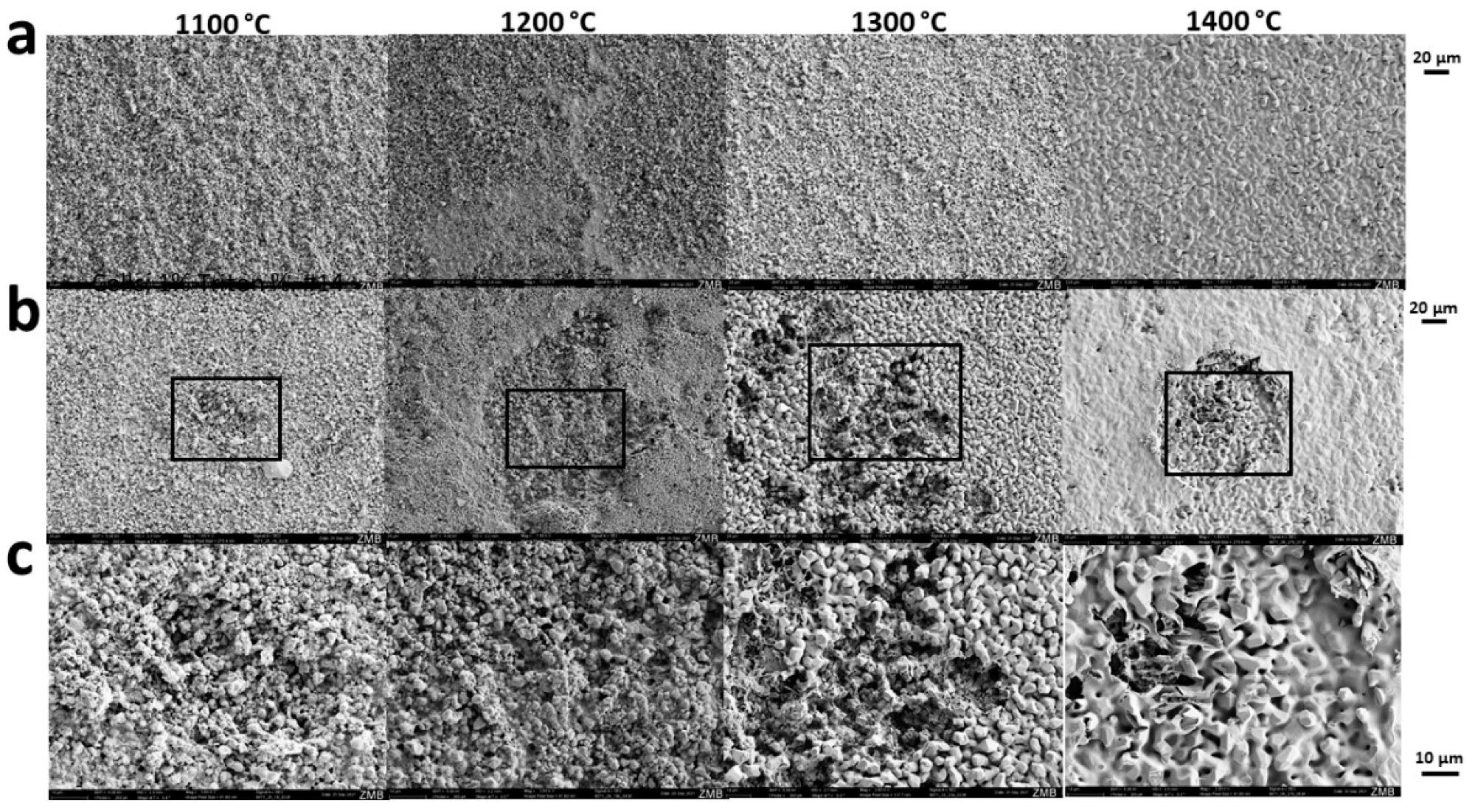

支架的烧结 - 温度依赖性的破骨细胞降解。扫描电子显微镜是从未暴露于细胞的脚手架上进行的(一种)或接种并暴露于破骨碎片刺激的RAW264细胞((b,c)。The maximal sintering temperature is provided at the top of each column. Scales of each panel are provided. Image Credit: Ghayor, C et al., Materials

结论

The positive impact of microporosity on osteoconduction in TCP-based scaffolds prompted the researchers to study the impact of microporosity on osteoconduction in HA-based scaffolds. The results showed that HA-based scaffolds had high osteoconductivity without depending on the microporosity. Also, they were considered more qualified for bone recovery methods.

Besides, microporosity somewhere in the range of 0 and 46% had no significant impact on osteoclast arrangement and osteoclastic resorbability. Hence, according to the researchers, microporosity had not influenced osteoconductivity or osteoclastic resorbability. These discoveries pave the way for future improvements in 3D-printed calcium phosphate-based scaffolds.

Source

Ghayor, C.; Bhattacharya, I.; Guerrero, J.; Özcan, M.; Weber, F.E. 3D-Printed HA-Based Scaffolds for Bone Regeneration: Microporosity, Osteoconduction and Osteoclastic Resorption.欧洲杯足球竞彩2022,,,,15,,,,1433。https://www.mdpi.com/1996-1944/15/4/1433

免责声明:此处表达的观点是以其私人身份表达的作者的观点,不一定代表AZOM.com的观点有限的T/A Azonetwork本网站的所有者和运营商。此免责声明构成了条款和条件使用此网站。