Researchers uncover new avenue for overcoming the performance decline that occurs with repeated charge-discharge cycling in the cathodes of next generation batteries.

Battery-powered vehicles have made a significant dent in the transportation market. But that market still needs lower cost batteries that can power vehicles for greater ranges. Also desirable are low-cost batteries able to store on the grid the intermittent clean energy from solar and wind technologies and power hundreds of thousands of homes.

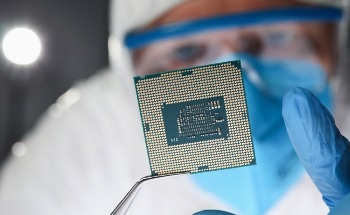

To meet those needs, researchers around the world are racing to develop batteries beyond the current standard of lithium-ion materials. One of the more promising candidates is the sodium-ion battery. It is particularly attractive because of the greater abundance and lower cost of sodium compared with lithium. What's more, when cycled at high voltage (4.5 volts), a sodium-ion battery can greatly increase the amount of energy that can be stored in a given weight or volume. However, its fairly rapid performance decline with charge-discharge cycling has stymied commercialization.

美国能源部(DOE)Argonne国家实验室的研究人员发现了绩效降解的关键原因:在准备阴极材料的步骤中形成的原子结构中的缺陷发生。这些缺陷最终导致阴极的结构地震,导致电池循环过程中灾难性的性能下降。凭借这些知识,电池开发人员现在将能够调整合成条件,以制造较高的钠离子阴极。

Key to making this discovery was the team's reliance on the world-class scientific capabilities available at Argonne's Center for Nanoscale Materials (CNM) and Advanced Photon Source (APS), both of which are DOE Office of Science user facilities.

“这些能力使我们能够在合成阴极材料的原子结构中实时跟踪原子结构的变化,”said Guiliang Xu, assistant chemist in Argonne's Chemical Sciences and Engineering division.

在阴极合成过程中,材料制造商将阴极混合物慢慢加热到空气中的高温,将其固定一定的时间,然后迅速将温度降至室温。

Compilation of the top interviews, articles, and news in the last year.

Compilation of the top interviews, articles, and news in the last year.