经过Surbhi JainMay 18 2022Reviewed by Susha Cheriyedath, M.Sc.

经过Surbhi JainMay 18 2022Reviewed by Susha Cheriyedath, M.Sc.

在最近发表在《杂志》上的文章中增材制造信,研究人员提出了一种弹性塑性断裂机械方法,用于评估添加性生产和铸造AL-SI合金的均匀疲劳损伤耐受性。

Study:均匀制造和铸造AL-SI合金的均匀疲劳损伤耐受性评估:一种弹性塑料机械方法。Image Credit: Alex_Traksel/Shutterstock.com

背景

添加剂制造(AM)和铸造允许精确创建针对本地负载流量的复杂外部和内部几何以及刚度。由于其出色的可铸性和低密度,铝合金(AL-SI)合金被广泛用于汽车和铁路工业。

尽管近几十年来,AM和铸造方法有所改善,但只能减轻过程引起的断层,而不能完全阻止。结果,对于高度负载零件的安全设计,必须适当考虑过程引起的故障。

村上的技术和根据村上诺加奇的方法对轻质金属合金的通常修改可用于描述缺陷对疲劳强度的影响。

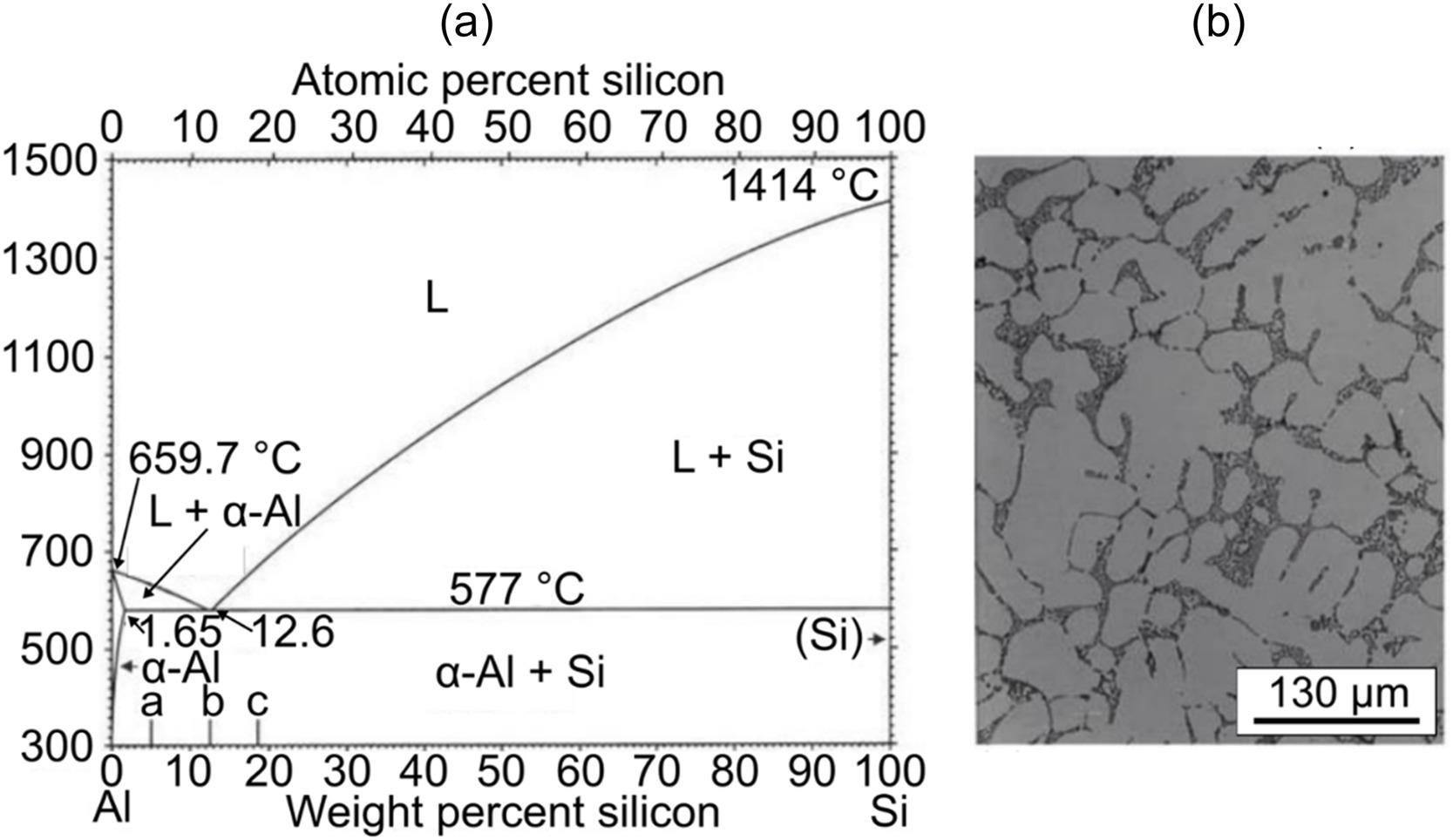

(a)二元Al-Si相图和(a)含有树突状α-固体溶液(光面积)和树枝状al-si Eutectic(黑暗区域)的含有树突状α-固体溶液(光面积)的二元显微照片。图片来源:Tenkamp,J。等人,添加剂制造信

关于研究

在这项研究中,作者讨论了基于穆拉卡米和Shiozawa的断裂机械技术的均匀破坏耐受性评估的开发,以实现可靠的基于缺陷的疲劳结构的机械设计。

穆拉卡米和Shiozawa的线性弹性断裂机械(LEFM)方法用于计算基于缺陷的寿命曲线,其中循环应力强度因子(ΔK)处于失败缺陷处(√area) was used to describe local stress concentration conditions, which resulted in K-N curves rather than nominal stress-based S-N curves.

研究人员通过计算有效的循环J积分(δJJ J J J J J J J J J J,采用了循环应力应变(CSS)行为来修饰LEFM技术。eff)绘制称为KJ-N曲线的基于J的K-N曲线。

For additively made and cast Al-Si materials, the effect of the process-induced microstructure, flaws, porosity, and stress-strain behavior on fatigue and fatigue damage-tolerant (FDT) behavior was investigated.

使用激光束(PBF/lb)的动力床融合来处理ALSI10MG材料,而砂粉(SC)和压铸(DC)用于制造铸件ALSI7MG材料。欧洲杯足球竞彩对AM材料进行了评估,而铸造材料则根据孔隙度,共晶Si沉淀,树突间距和冷却速率进行调整。欧洲杯足球竞彩拉伸和增量步骤测试分别确定准静态(QSS)和CSS特性。

该小组研究了AM和铸造方法对缺陷分布,微结构,疲劳行为和CSS的影响,对特定于过程的标准AL-SI合金ALSI10MG和ALSI7MG。为了确定其局限性,回顾了当代方法论进行损害耐受性评估。

Furthermore, the findings were coupled to novel elastic-plastic fracture mechanical techniques in order to overcome these limitations and allow for a unified fatigue damage tolerance assessment of AM and cast Al-Si alloys. The fatigue behavior was described using both traditional and new methodologies, including Murakami-relativized Noguchi's S-N curves and Woehler's S-N curves based on estimated hardness- and defect-based fatigue limits.

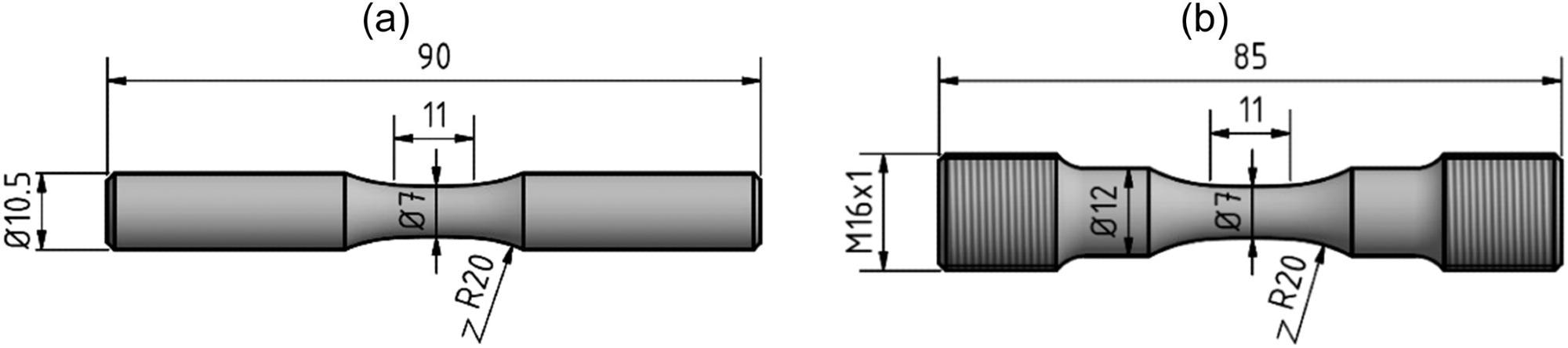

几何:(a)应变控制的拉伸和LCF测试;(b)应力控制的HCF测试。图片来源:Tenkamp,J。等人,添加剂制造信

观察

For compression-tension loading, the fatigue limit of AM alloy was dramatically reduced, especially when the ratio of compressive loading (stress ratio, R) was raised to -2. Furthermore, for R = -1, stress sensitivity increased as defect size decreased.

当R等于0.1时,与R等于-1时,发现FDT要低得多。AM具有与选定的SC和DC相当的准静态屈服强度(Ys),但是0.02%的Ys较低,最终的拉伸强度更高。SC1的Ys最终超过了DC1的YS 5%。DC1P2-QSS曲线的应变硬化系数降低多达10%。对于DC1P2和DC1,环状应变硬化系数分别增加了22%和7%。

无法通过使用基于LEFM的K-N曲线的统一疲劳设计和铸造材料的统一疲劳设计来描述疲劳行为。EPFM方法允许对HCF制度对AM和铸造AL-SI合金进行统一的FDT评估。

AM材欧洲杯足球竞彩料具有更高的准静态强度,但循环强度较高,而铸造材料的循环强度则更高,而铸造材料由于具有明显的循环钢化特性而具有更高的循环强度。穆拉卡米 - 诺格奇能够正确预期铸造材料的疲劳极限,但是AM材料的疲劳极限被高估了。欧洲杯足球竞彩

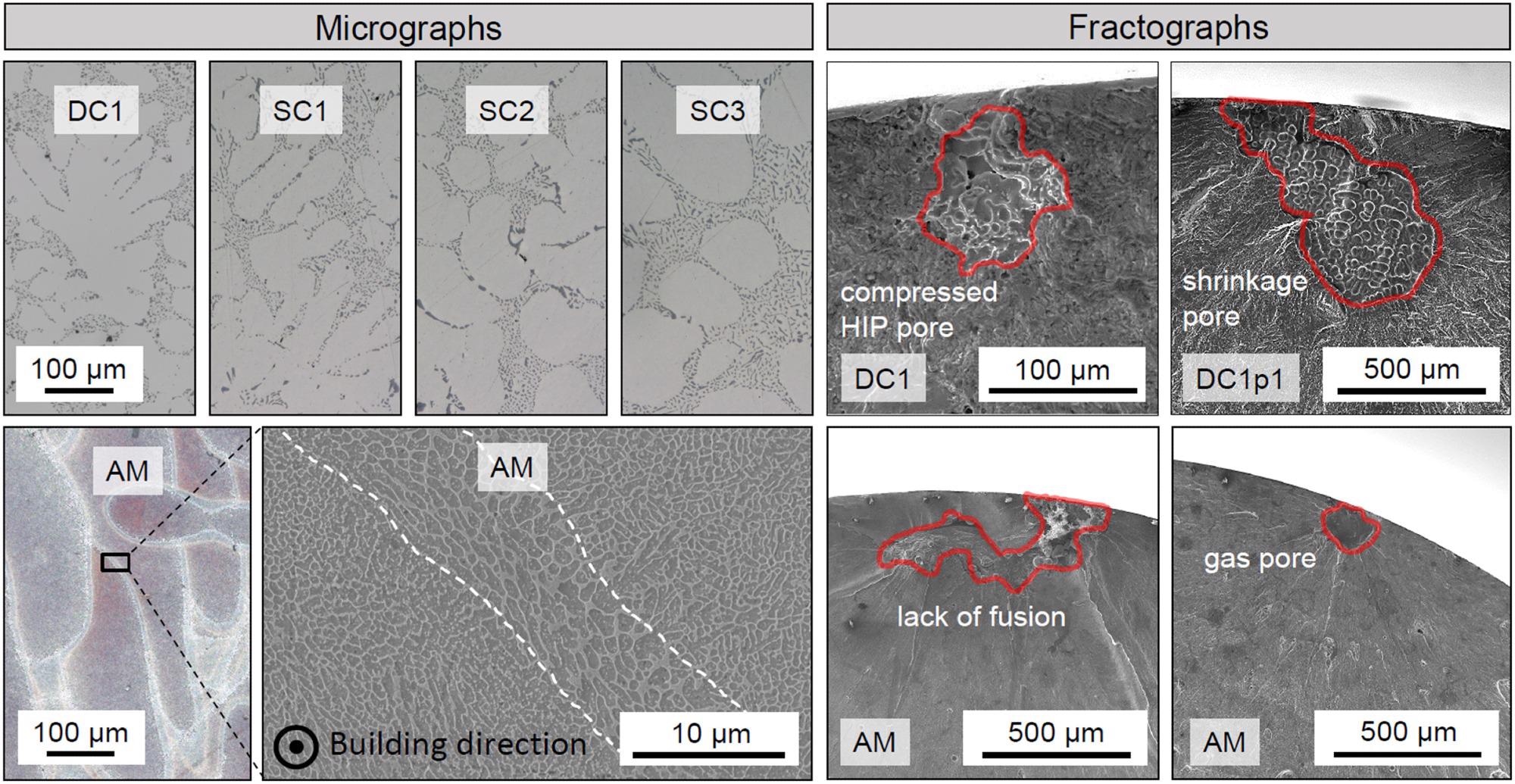

代表性OM和SEM显微照片(左)以及DC和SC ALSI7MG合金(TOP)和AM ALSI10MG合金(底部)的SEM隔板(右)(右)。图片来源:Tenkamp,J。等人,添加剂制造信

结论

总之,这项研究阐明了J积分向应力强度因子(SIF)维度(称为J-SIF或KJ)的翻译,该维度被称为J-SIF或KJ,该维度使用KJ-N曲线用于基于J的Shiozawa图。无论过程特异性的微结构,可塑性或孔隙率特征如何,这种变化都可以进行一致,准确的FDT评估。结果,可以发现针对HCF制度的标准FDT立法以及FDT限制或疲劳限制。

The authors mentioned that using the cyclic stress-strain behavior, specific defect distribution, and stress ratio, the uniform FDT limit, and the uniform FDT law may be utilized to construct Haigh diagrams and synthetic S-N curves for Al-Si alloys.

Source

Tenkamp,J.,Stern,F.,Walther,F。,对添加性生产和铸造Al-Si合金的均匀疲劳损伤耐受性评估:一种弹性塑形断裂机械方法。增材制造信100054(2022)。https://www.欧洲杯线上买球sciendirect.com/science/article/pii/s27772369022000287

免责声明:此处表达的观点是以其私人身份表达的作者的观点,不一定代表AZOM.com的观点有限的T/A Azonetwork本网站的所有者和运营商。此免责声明构成了条款和条件使用此网站。