在最近发表在《杂志》上的文章中Additive Manufacturing,研究人员讨论了体积添加剂制造的即时计量学。

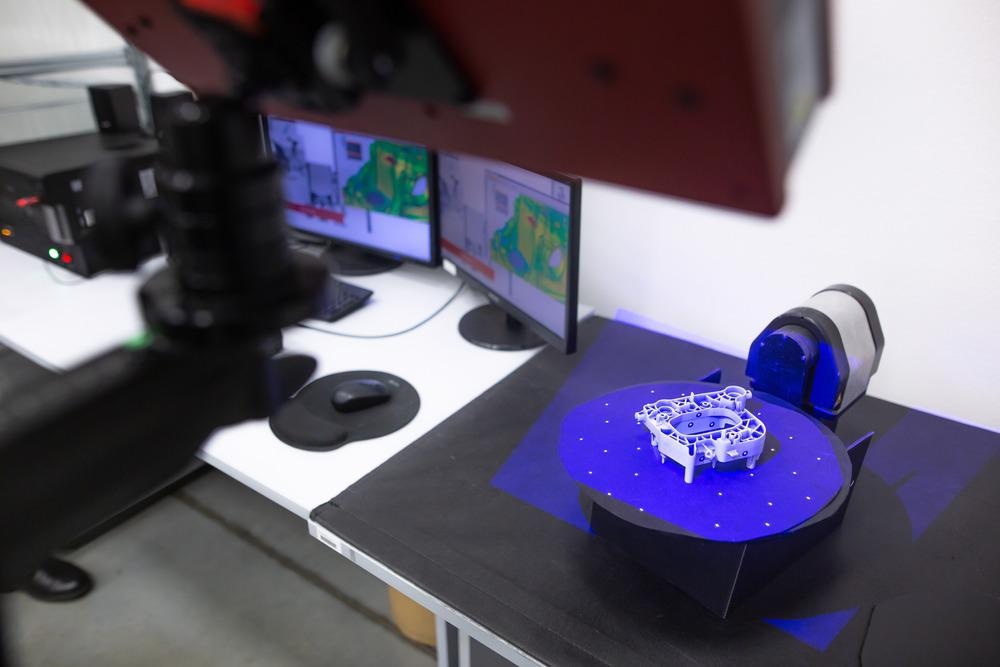

学习:体积添加剂制造的即时3D计量学。图片来源:Simon Kadula/Shutterstock.com

Background

体积添加剂制造(VAM)的最新进展改变了增材制造(AM)范式。VAM技术可以同时快速3D打印所有层,而不是逐层逐步构建项目。层析成像VAM目前是最广泛使用的VAM方法。

While VAM has facilitated the AM speed to new heights, the necessity for rapid print metrology and inspection remains a major barrier across all AM modalities. In situ AM metrology is now restricted to evaluating local material properties. There is currently no device that can accurately assess the geometry of a complete object during or after printing.

尽管需要在所有AM方法中进行实时几何监测,但VAM尤其要受益。要处理VAM的暴露时间灵敏度,必须确定最佳的曝光时间。尽管这一实际问题在VAM文献中很少强调,但它排除了可再现和准确的印刷结果。

关于研究

In this study, the authors discussed fully simultaneous 3D metrology and printing. For real-time 3D imaging, a photo-resin's substantial increase in light scattering during gelation was incorporated. During tomographic volumetric additive manufacturing, prints were imaged. The light scattering density in the build volume was imaged to produce quantitative, artifact-free 3D + time models of cured items that were accurate to within 1% of the print size.

The team presented an optical imaging approach for the real-time 3D mapping of the curing process in AM. The dramatic increase in light scattering caused by a resin during gelation was used to discriminate between cured and uncured print volume regions.

High contrast projection images of the print were obtained by monitoring the scattering light intensity within the volume built in a darkfield configuration. In the proposed optical scattering tomography (OST), side-scattered light from the volume of the print was scanned as it spun to form a sinogram of every layer of the object and allowed tomographic reconstruction.

研究人员展示了复杂的断层造影印刷品的4D成像,并将OST成像发现与参考打印几何形状进行了比较。

Observations

与凝胶化相对应的散射密度可以可靠地校准,从而导致打印重建精确地达到打印尺寸的1%以内。有人发现,即使是像能力这样的复杂物体,也可以使用OST进行层压结构。OST成像系统极大地加速了在广泛的印刷几何形状和树脂上获得成功打印参数的能力。

The cured monomer was highly scattering and bright, while the uncured monomer was black. The rotating build volume allowed for simultaneous tomographic dose projection and tomographic imaging. The real-time nature of OST print imaging also enabled the user to pinpoint the source of print errors. OST also removed the trial and error associated with discovering new print times.

据观察,OST允许操作员适应由温度波动引起的打印速度的变化以及回收树脂时。OST除了成为最终用户打印机操作的重要工具外,还可以用于研究光聚合动力学。

The darkfield imaging of scattered light during the gelation process was a significant component of the proposed metrology approach. This optical configuration was useful in tomographic VAM, but it could also be employed in other AM approaches.

结论

总之,这项研究介绍了OST成像方式,该模式允许对层析成像VAM工艺进行实时3D成像。作为一种光学对比机制,OST剥削了由液体单体和固体聚合物之间的微尺度折射率差异引起的散射。尽管在VAM打印过程中发生了弱的内部散射,但通常在固化物体获得同质折射率时,通常会降低它,从而产生良好的内部清晰度的印刷品。

Rayleigh scattering theory captured the approximate dependency of the OST scattering signal on the refractive index mismatch. The dimensional accuracies and root-mean-square errors (RMSE) of experimental OST-derived 3D models and reference geometries were often less than or equal to the OST voxel size of 0.155 mm or around 1% of the size of the print. This result suggested that the proposed tomographic print system achieved a state-of-the-art and novel VAM print fidelity.

The authors believe that easy-to-use spatial-temporal metrology, such as that offered by OST, will be crucial in improving the fidelity of tomographic VAM while also making it more accessible to end-users. They also mentioned that the findings of this study lay the way for next-generation fast prototyping with real-time fault identification and correction by including form measurement in the printing process.

来自AZOM的更多内容:基于同步加速器的X射线荧光显微镜的应用

来源

Orth, A., Sampson, K. L., Zhang, Y., et al. On-the-fly 3D metrology of volumetric additive manufacturing. Additive Manufacturing 102869 (2022).https://www.欧洲杯线上买球sciendirect.com/science/article/abs/pii/s2214860422002688

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of theTerms and conditions使用此网站。