经过Surbhi Jain7月11日2022年Reviewed by Susha Cheriyedath, M.Sc.

经过Surbhi Jain7月11日2022年Reviewed by Susha Cheriyedath, M.Sc.

在最近发表在《开放式杂志》上的评论中能量, researchers discussed new research trends regarding proton exchange membrane fuel cells.

Study:质子交换膜燃料电池的新趋势。Image Credit: PixelSquid3d/Shutterstock.com

背景

有效利用可再生能源的基本先决条件是开发环保和高效的能源转化技术。燃料电池(FCS)是电化学系统,与各种可再生能源一起使用时显示出令人鼓舞的结果。由于氢对环境没有不利影响,可以使用电解和其他技术从水中产生,因此被认为是未来的燃料。预计对能源产生部门产生最大影响的最典型类型的FC是低温质子交换膜燃料电池(PEMFC)。

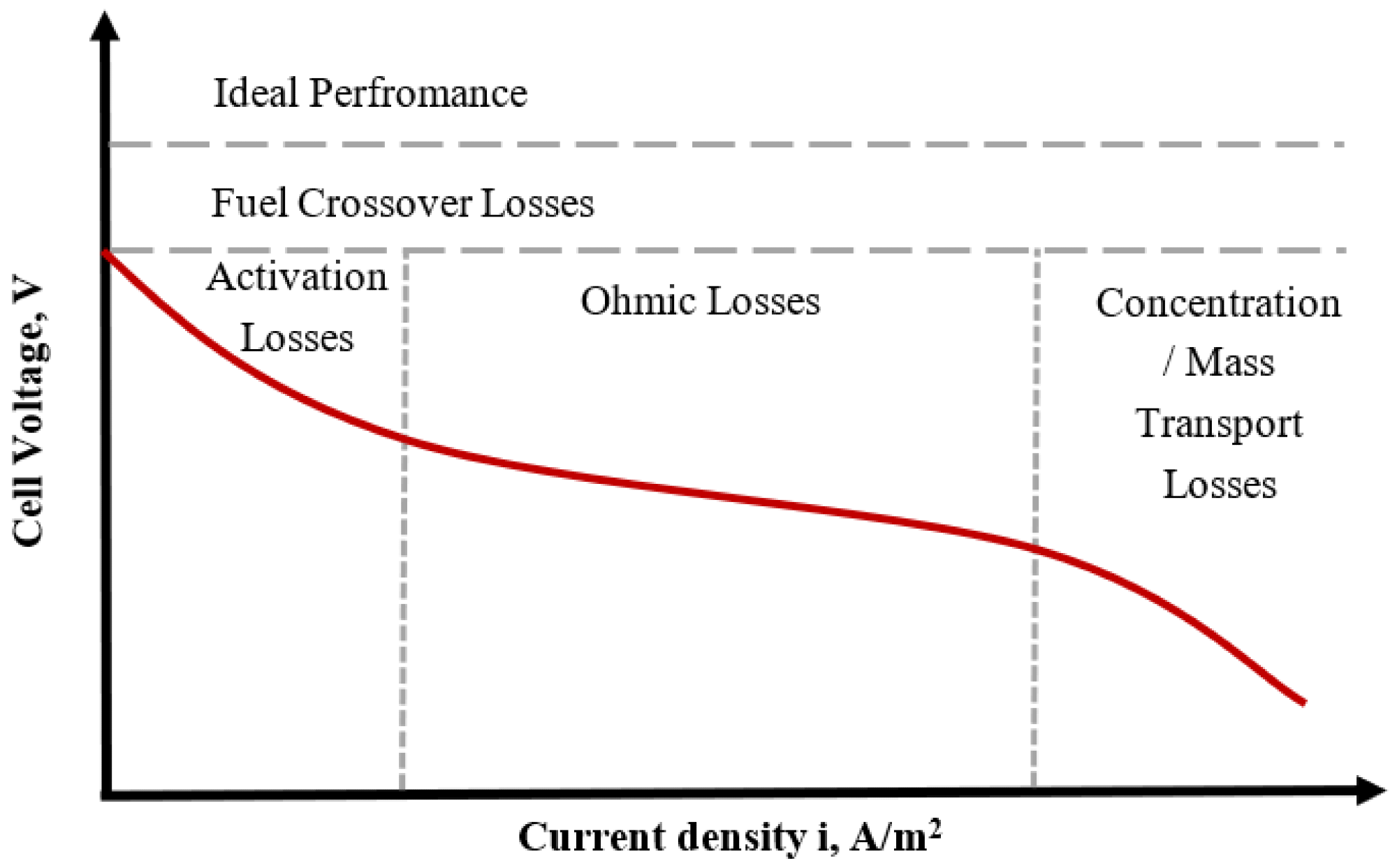

Despite the fact that PEMFCs have several benefits, their commercialization is constrained by competition from traditional combustion engines. In the most recent few decades, the creation of inexpensive yet long-lasting FCs has advanced more quickly. Before PEMFCs can successfully replace conventional power systems, they must first address a number of problems. The potential for adoption of this technology is mostly influenced by the price per kW of the FC system and the availability of hydrogen supply. New supply routes for hydrogen have been given in a number of studies; however, the price is still high. Additionally, in order to make this market lucrative and accessible to more users, the producers must lower manufacturing costs and, as a result, the price per kW.

Polarization curve with the electric losses’ regions encountered with the operation of PEMFC (adapted from [28] (license no. 5172430728078)). Image Credit: Olabi, A. G et al., Energies

关于研究

在这项研究中,作者研究了质子交换膜燃料电池(PEMFC)的许多部分以及它们的制造方式。这些制造方法面临的困难得到了彻底检查,并提出了一些解决方案。

The team presented a thorough analysis to understand the current state of fuel cell operational characteristics and identified new areas for development in the young and evolving PEMFC technology. The theory covered in this study was intended to help fuel cell development in some way.

The researchers investigated and critically examined the present and cutting-edge materials utilized for PEMFCs, as well as their characteristics and the numerous fabrication processes used to make FC components.

![Schematic diagram of membrane electrode assembly [37] (open access).](https://d12oja0ew7x0i8.cloudfront.net/images/news/ImageForNews_59526_16575288351409007.png)

Schematic diagram of membrane electrode assembly [37] (open access). Image Credit: Olabi, A. G et al., Energies

观察

液体弹性体可以在15秒内固化,并达到0.4英寸的厚度。根据调查结果,SS304纸皱纹并以非常不同的速度断裂,速度更高的速度在0.1至1.1 m/s之间。与溅射相比,电子束还原电极更有效,最佳功率密度为0.56 W/cm2for the former and 0.36 W/cm2for the latter.

Contact resistance between gas diffusion layers (GDLs) and bipolar plates (BPs) could result in the loss of up to 59% of the power in PEMFCs. Metals corroded at faster rates than gold, which had a rate of less than 15 m/year and was comparable to graphite. Metals corroded at rates of roughly 250 and less than 100 m/year for aluminum and stainless steel, respectively.

The Nafion membrane provided the best performance in terms of materials for the catalyst layer and membrane, but it was still expensive. The performance suffered, and the cost increased as a result of attempts to lower the Nafion and platinum concentration. The current focus was on finding new materials that could entirely replace both platinum and Nafion. Corrosion was a significant issue for the BPs, and this is being addressed with coatings. The performance of attempts to create alternative materials to replace metals was not yet equivalent. As a result, attempts were made to create brand-new coating processes that were more effective.

挠度是端板的主要问题,尤其是对于具有很多单元的堆栈而言。可以通过选择具有较高拉伸强度但重量低的材料来解决此问题。

。](https://d12oja0ew7x0i8.cloudfront.net/images/news/ImageForNews_59526_16575288542059809.png)

((a,b)PEMFC的示意图显示螺栓和螺母;(C)遇到夹紧压力时MEA发生的事情的图;(d)diagram for a unit cell;(e)夹紧压力和应变;(F)relationship between clamping pressure and contact resistance [134] (license no. 5175230250109). Image Credit: Olabi, A. G et al., Energies

结论

In conclusion, this study examined the materials and production of the various PEMFCs. A lot of attention was paid to the unique PEMFC materials and their qualities, and fabrication techniques for making PEMFC components were also investigated.

The membrane electrode assembly was one of the components reviewed. The authors mentioned that the PEMFCs have advanced, but there are still issues with cost and durability that must be resolved before they can be implemented widely. Low power density and mechanical durability are issues for the FC.

他们还指出,尽管在过去几十年中的研究和优化方面取得了所有进步,但PEMFC是一项独特的能源转换技术,因此仍有开发机会。

Source

Olabi,A。G.,Wilberforce,T.,Alanazi,A。等。质子交换膜燃料电池的新趋势。能量15(14)4949(2022)。https://www.mdpi.com/1996-1073/15/14/4949

免责声明:此处表达的观点是以其私人身份表达的作者的观点,不一定代表AZOM.com的观点有限的T/A Azonetwork本网站的所有者和运营商。此免责声明构成了条款和条件使用此网站。